Distributor of Kimia sandwich panel in Isfahan

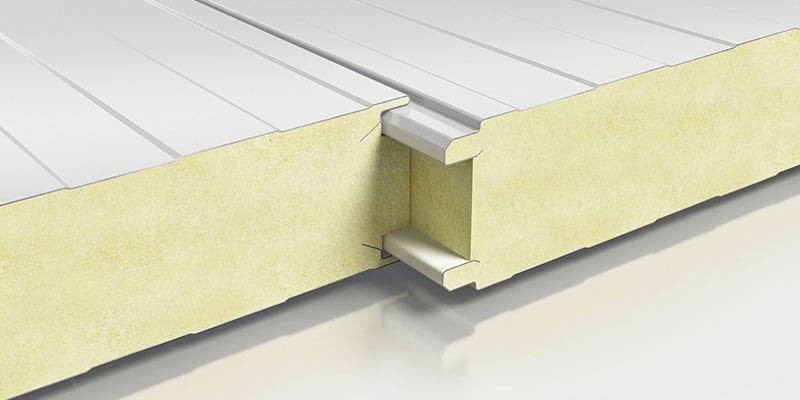

As a prefabricated product, sandwich panel has gained special popularity among structural engineers. Kimia Panel Company is one of the best companies in the field of sandwich panel production. Sandwich panels are produced and supplied with the aim of optimizing and reducing energy consumption and are a suitable alternative to traditional construction materials. One of the important advantages of this new product is the ability to install it in all kinds of weather conditions and fast installation performance. Sandwich panels have a coherent structure consisting of three composite layers. The upper and lower layers that are limited to the sheet, these two layers can be chosen from galvanized, aluminum, and aluzinc, and each of them has its own features and characteristics.

The material of these sheets is thin but very firm. The middle layer that covers the central nucleus. It is very light and thick. This product is called polyurethane foam, which can be covered with polyurethane foam, rock wool, polystyrene and XPS. Polyurethane material is a very light and flexible foam that has many features. We discussed this in detail in previous articles. Polyurethane foam has many advantages that we will mention here. It is light weight and easy to transport, it is waterproof and fireproof, and it is completely resistant to chemical agents and weather conditions.

Isfahan sandwich panel is divided into two general types; Wall sandwich panel and ceiling sandwich panel, sandwich panels for cold storage, clean room, shed and fireproof are part of this category.

Sandwich wall panel in Isfahan

As its name suggests, it is used to cover the walls of the structure. The upper and lower layers are made of galvanized sheet and aluzinc, and the core part of the panel is completed with polyurethane materials, which creates a light texture and structure. It has a reasonable price, it is very affordable in terms of cost and shows a lot of resistance. It is used to build the walls of sheds, prefabricated houses, houses, cold storages, condos, and clean rooms.

This product is divided into three categories against fire, fireproof, slow-burning and flammable wall sandwich panels. The wall sandwich panel can be designed and produced in various designs and models. The thickness defined for the wall sandwich panel between 4 and 10 cm is the best choice that can be used the most. The density of the middle core is about 40+_2 kg.

Wall sandwich panels are resistant to corrosion and moisture due to the upper and lower embedded sheets. The galvanized sheet protects the panel from corrosion due to its zinc layer and cathodic protection.

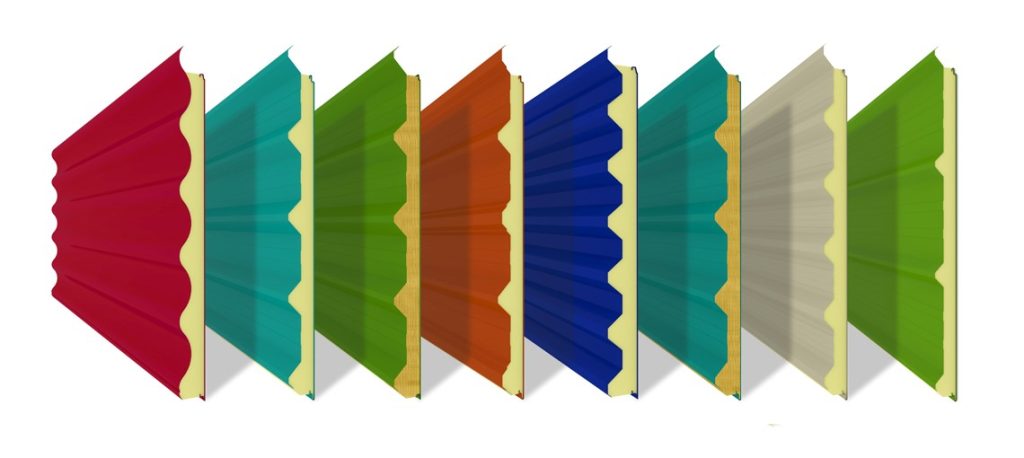

The aluminum sheet can be used alone, and one of the prominent features of this panel is its lightness and flexibility. The variety of sheet type increases the power of choice in the sandwich panel type. Sandwich panels have a wide variety of colors and increase the range of color selection, which is one of the advantages of sandwich panels.

Isfahan ceiling sandwich panel

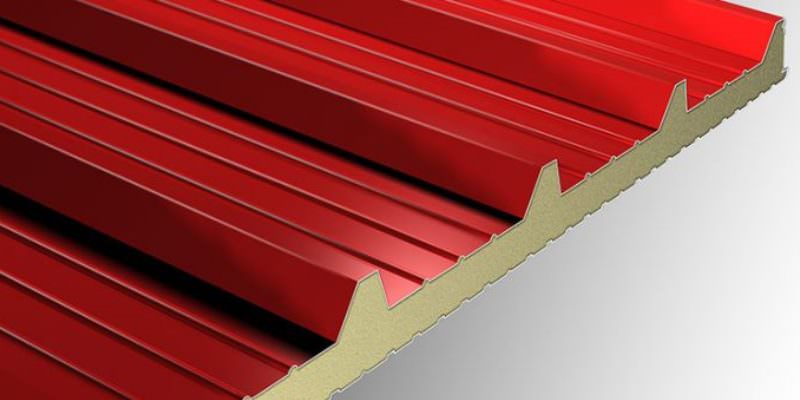

The most important part of a structure and building, which requires sufficient precision in terms of architecture, is the roof. This product is used for roofing the structure. In addition to beauty, Isfahan roof sandwich panel makes the roof of the structure stronger. The important feature of sandwich panels is that it is compatible with all weather conditions and can give us very good physical characteristics.

The salient features of this product are fire resistance and good sound insulation. Isfahan ceiling sandwich panel has two top layers of thin but strong sheet which is covered with polyurethane middle core. The foam embedded in the ceiling sandwich panel is composed of polyurethane.

It is very light weight and does not absorb any liquids and its durability is very high. The roof of any building is the most important part. It is more exposed to rain and snow. Therefore, the resistance and durability of its building materials should be good. The material of the sheet used in the ceiling sandwich panel is as follows, which are galvanized, aluzinc and aluminum, each of which has different characteristics. Of course, it is worth mentioning that the type of sheet can affect the price. If we want to divide the ceiling sandwich panel in terms of appearance, it is as follows;

Sandwich panel with two sheets, one sheet, one sheet with foil, one sheet with nylon, one sheet with foil, one sheet with paper, which can affect the final price.

Of course, in order to optimize the cost and reduce the price, the outer layer can be selected as a sheet and the inner layer, which is of little importance, can be considered from foil or kraft paper.

Application of Isfahan-Saghfi sandwich panel

- Schools and laboratories

- Mobile clinics and blood transfusion centers

- Public or private places

- Types of fixed and mobile cold storage

- False ceilings and indoor pools

- clean room

- Types of prefabricated buildings and sheds

Advantages of Isfahan sandwich panel

Isfahan sandwich panel has many features that we intend to express here in a scattered manner.

- Light weight of the structure and ease of transportation and installation

- Easy and fast installation and time optimization

- Heat, cold, sound and fire insulation

- Ability to recycle and reinstall

- Ability to wash and disinfect

- Resistance to decay, corrosion and moisture

- Reducing energy consumption and preventing heat and cold energy waste

- High quality, durability and longevity

- Earthquake resistant

- Resistant to insect infestation

Isfahan sandwich panel installation

After ordering and purchasing the sandwich panel, it is necessary to install it, and the installation steps are done according to the type and design, the type of structure and the dimensions of the project. Sometimes, other installation methods may be substituted, which do not require complex tools and much expertise, but should be done by efficient and experienced people. This prevents the panel from being thrown away and damaged.

In order to reduce and optimize the cost, you can choose a wall sandwich panel in the outer layer of sheet type, which is sometimes galvanized or aluzinc, and consider the inner layer to be made of paper, foil or nylon. One of the basic methods for installing sandwich panels is to use It is a corner and iron studs that make the skeleton with a 90 degree angle, and of course, it should be made with a lot of thickness. in such a way as to form a frame. Then the panels are placed inside the frame and next to each other and thus it is installed.

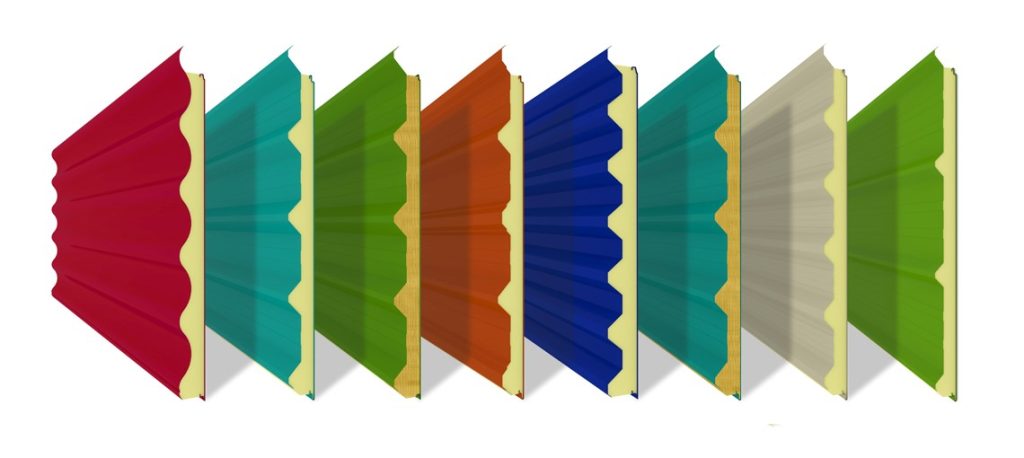

The edges of the panel, which are male and female, are inserted into each other. In this case, a narrow seam is created that can be covered with special silicone spray or glue. Another method that is considered for installation is hidden screws. This method is used for stronger structures. This requires panel overlaps to be placed along the metal column where the panel is screwed to the column and so that the screws are not visible in the work view. The sheet is bent in such a way that it is placed and covered on the screw at the junction of the next panel, and finally no screw will be visible.

Isfahan sandwich panel price

The price of sandwich panel depends on many factors that were explained in detail in previous articles. These factors include the size, thickness of the panel, type of sheet, density, how the quality of the brain is connected to the surfaces and the quality of the production process determine the price of the sandwich panel. The price is estimated per square meter. The middle core of the sandwich panel is definitely effective on the quality of the final product and the price. Sandwich panels are made of two sheets, the type of sheet can be chosen from galvanized, aluminum, and aluzinc, but to reduce the cost, you can consider foil, nylon, or kraft paper. took

Kimia Panel Company, with several years of useful and productive experience in the production of polyurethane sandwich panels, is a leader in the production of ceiling and wall sandwich panels, clean rooms and concourses, using the best raw materials available in the market and benefiting from expert and skilled forces with The expert and experienced sales team is at your service. For detailed information on the price and order of the products, you can contact us with the numbers listed at the bottom of the page or through the social networks available on the contact page.

Related articles

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Polyurethane sandwich panel, Types of sandwich panels

- Buy sandwich panel in Isfahan, Buy wall sandwich panels in Isfahan, Buying and selling wall sandwich panels in Isfahan, Buying ceiling sandwich panels in Isfahan, Implementation of sandwich panel in Isfahan, Isfahan sandwich panel, Isfahan sandwich panel ceiling, Isfahan wall sandwich panel, Price of ceiling sandwich panel in Isfahan, Sale of ceiling sandwich panels in Isfahan, Sales agent of ceiling sandwich panels in Isfahan, Sandwich panel price in Isfahan, Sandwich panel price list in Isfahan, Selling sandwich panels in Isfahan, Selling wall sandwich panels in Isfahan, Wall sandwich panel price in Isfahan, Wall sandwich panel price list in Isfahan