Introduction to polyurethane sandwich panel

Is sandwich panel an alternative to prefab tools? As we know, with the passage of time and progress of life, everything is changing and construction structures have also changed.

In other words, the materials used for construction in the world are progressing daily. The best performance of a building material will be when less energy and cost are required for its implementation;

While this will have an acceptable result and quality. For this reason, modern engineering science is moving in a direction that can reduce the amount of energy consumed and reduce costs significantly.

In this way, industrial or even semi-industrial systems came to work and caused the boom of semi-prepared structures. You may have heard many times that a certain town or a certain part of a country is completely prepared with prefabricated instruments. The speed of construction with prefabricated structures is so high that normal projects can be completed within a month. Semi-ready or prefabricated structures are in a form that reduces financial costs, project duration, labor, required materials, etc. and also have high security.

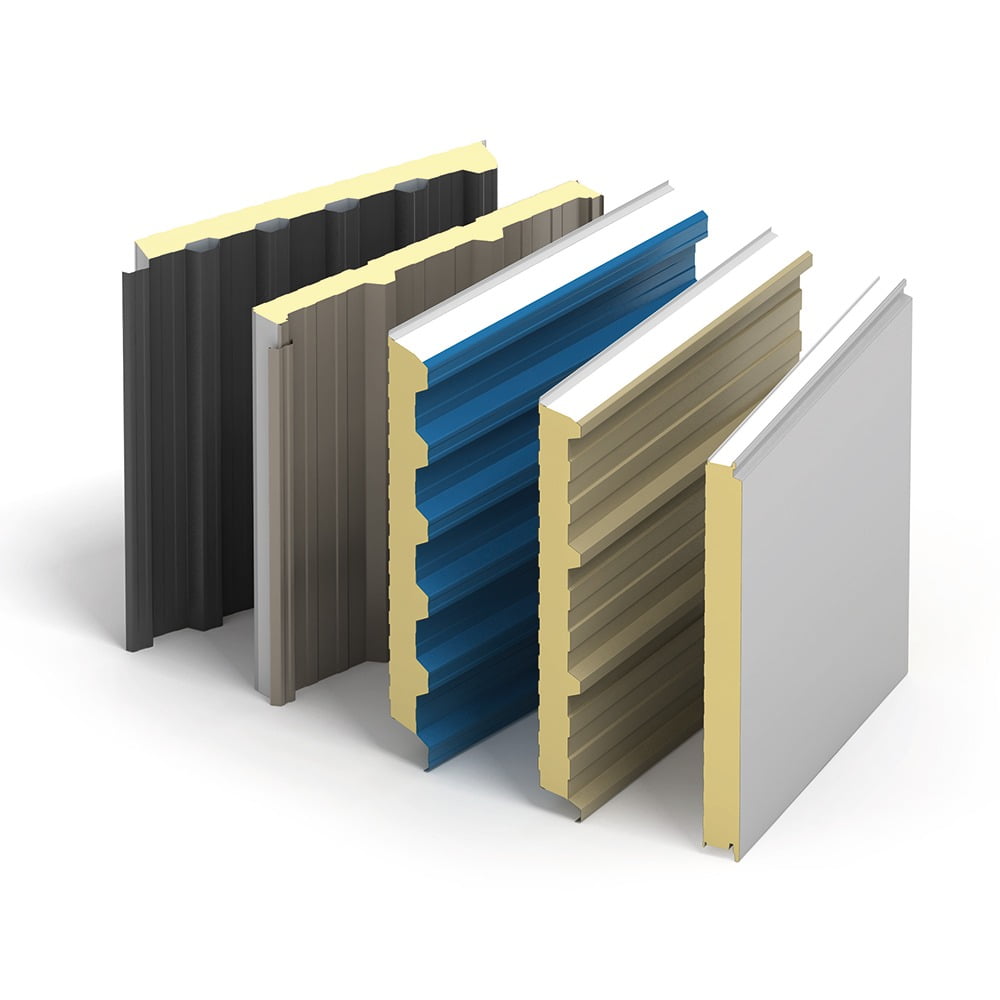

Types of sandwich panels

At the beginning and before stating any point, we should know that sandwich panels have several wall and ceiling types. All its models have high quality and life and are effective for different projects. In this part of the article, it is necessary to know that the polyurethane sandwich panel is one of the most important and best types of these ready-made structures, which is the first word in terms of insulation, and we can boldly say, it is the best of its kind.

What is the security and efficiency of polyurethane sandwich panels or prefabricated structures?

As we know, the general goal of civil or building structures is to maintain the security and high resistance of the structures. In other words, we used concrete or steel structures, because very high resistance is achieved in their combination. These days, sandwich panels are not only very strong and safe, but they are already made and will not require much time for execution and molding.

As we know, the general goal of construction or building structures is to maintain the security and high resistance of the structures. In other words, we used concrete or steel structures, because very high resistance is achieved in their combination. These days, sandwich panels are not only very strong and safe, but they are already made and will not require much time for execution and molding.

As we know, concrete structures with steel reinforcements have high resistance; This is despite the fact that they are not only heavy, but they will need a lot of time to perform. On the other hand, we know that the structures must have a small weight so that we can reduce their resistance against the force of the earthquake. In other words, when the structure prepared from any type of material has a high weight, its resistance against earthquakes decreases.

Meanwhile, sandwich panels have very little weight and will have higher earthquake resistance. For this reason, we recommend you, dear ones, to increase your information in this field and learn important things by reading this article.

What are the advantages of polyurethane sandwich panels?

In the above lines, we concluded that the sandwich panel is very useful for earthquake resistance due to its light weight. Next, we should know that this prefabricated structure has other advantages. For example, we can mention its energy insulation. As you know, these days we are all trying to reduce energy consumption. The use of sandwich panels is very suitable for reducing the waste of heat and thermal energy.

On the other hand, this structure is ready in advance and does not have any construction debris, and this issue has increased its supporters. When a building or structure is prepared with traditional materials, they have wastes that are very annoying and a part of the city should be dedicated to this task to maintain them. This is despite the fact that there is a lot of pollution and it is harmful. On the other hand, when demolishing traditional structures, all materials must be thrown away.

Despite the demolition or reconstruction of structures made with sandwich panels, there is no construction waste and its materials can be recycled. As we know, recycling is one of the most important things that will have a great impact on the environment of our lives. While old construction materials are not recyclable and should be thought about.

Also, high installation speed, simple and effortless installation, durable life, etc. are other advantages of polyurethane sandwich panel. As you have seen, none of the types of building materials have the efficiency and advantages of these structures and they cannot be implemented at a very high speed. For this reason, most successful engineers have work experience in this field and know that the implementation steps will be as follows.

Applications of polyurethane sandwich panels

In the previous parts, we briefly stated the advantages of polyurethane sandwich panels, now we are going to talk about their applications. As we know, such functional materials have high fans and they will be used for walls and ceilings. The walls and ceilings are the main members of the structure and will determine the main load of the building. For this reason, when we use prefabricated structures in these two cases, the security and resistance of the structure will definitely increase. This case is very useful for the earthquake-prone cities of Iran and it will reduce the human and financial damages of this natural event.

In addition, it is necessary to know that polyurethane sandwich panels are used for any type of residential, commercial, sports, large sheds, etc. and have the necessary efficiency. Instead of increasing your financial and time costs, you can consult with engineers related to this field and, if approved, proceed to implement it. It should be noted that sandwich panels will be used in certain environments due to their very high advantages. For example, we can refer to sterilized environments.

Appearance characteristics of polyurethane sandwich panel

It is necessary to know what kind of appearance features the prefabricated structures have that could have such a high amount of resistance. In general, sandwich panels have a row as a rigid material and there are special sheets around it. These mentioned sheets have relatively high flexibility and were made to protect the brain between them. It is also necessary to know that the brain in question is made of polyurethane. This different appearance has caused sandwich panels to have certain differences.

Another thing to mention is that the mentioned brain may be made of stone wool. Anyway, this brain should have high resistance and light weight at the same time. We definitely know that light weight will have a great effect on reducing the anchor and on the other hand reducing the force of the earthquake. In some cases, polystyrene is also used for the mentioned brain. We advise you to fully consult with your executive engineer before ordering the prefabricated panel and describe the type of efficiency of this structure; So that you can buy the best type of panel.

What is polyurethane and what is its use?

It may be necessary to know a little about polyurethane in order to better understand the effectiveness of polyurethane sandwich panels. Polyurethane is made from chemicals and is one of the most popular polymers in the world. Usually, the core or middle row of all sandwich panels is made of polyurethane. Because this material has high insulating properties and can be useful in all practical cases. In other words, in most factories or commercial sheds, prefabricated polyurethane walls and ceilings are used, and for this reason, its many advantages can be understood.

Remarkable points in sandwich panel installation

As you were with us in the above lines, the installation and use of polyurethane sandwich panels is different from other construction materials and we must provide you with useful information in this regard. Stay with us. First of all, we should know that the installation of sandwich panels is so fast that it will surprise the employer. This is despite the fact that the installation of prefabricated structures has its own principles and should not be ignored.

In general, there are two types of sandwich panels, which must be placed one in between with a distance during installation. In other words, the panels are produced in two types, male and female, and at the time of installation, these two items must be next to each other. The reason for insisting on having a male panel and a female panel next to each other is that they will be secured together. For this reason, at the time of installation, the installer must be a person with high precision.

As expected, if the installation of prefabricated structures or the same panels is not done correctly, they will definitely not have the mentioned resistance and advantages. When you can have a very beautiful and resistant structure, if the utmost care is taken in the installation and the principles of its installation are properly observed.

Conclusion: In the end, all the above can be said in this way that sandwich panels are prefabricated structures that will have countless advantages. Among these advantages, we can mention insulation, high execution speed, easy installation, no construction waste, recycling, different beauty, etc. Meanwhile, most Iranian engineers work in the field of installing and implementing prefabricated structures and are very successful.

On the other hand, you need to know that the best type of sandwich panels is their polyurethane model. This model has a very powerful insulation and compared to other models, it will have a better reduction in energy consumption. We know that these days we should try to save energy and it will not be time to use them excessively. Among the types of polyurethane sandwich panels, we can mention its ceiling and wall type.

These prefabricated structures will be used and applicable in sheds, factories, companies, residential structures, etc. At the time of their installation, pay attention that the principles of installation are implemented correctly and that the male and female panels are properly next to each other. In other words, the existence of all the advantages of sandwich panels is related to their correct installation, and otherwise, high resistance cannot be expected from them. For this reason, take the correct installation of prefabricated structures seriously.

Thank you for reading this article.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- all, Cold room sandwich panel, Duct panel, Polyurethane sandwich panel, Roof sandwich panel, Types of sandwich panels, Wall sandwich panel

- Buy ceiling sandwich panels in Shiraz, Buy sandwich panels in Shiraz, Buy sandwich wall panels in Shiraz, Buying a condo in Shiraz, Installation of ceiling sandwich panels in Shiraz, Installation of sandwich panels in Shiraz, Installation of wall sandwich panels in Shiraz, Roof sandwich panel, Roof sandwich panel in Shiraz, Roof sandwich panel installer in Shiraz, Sandwich panel, Sandwich panel in Shiraz, Sandwich panel installer in Shiraz, Sandwich wall panel in Shiraz, Selling ceiling sandwich panels in Shiraz, Selling sandwich panels in Shiraz, Selling wall sandwich panels in Shiraz, The price of ceiling sandwich panel in Shiraz, The price of sandwich panels in Shiraz, The price of wall sandwich panels in Shiraz, Types of sandwich panels, Types of sandwich panels in Iran, Wall sandwich panel, Wall sandwich panel installer in Shiraz