Technical specifications of wall sandwich panels in Shiraz

Kimia sandwich panel consists of three composite layers, which are bounded by steel sheets on both sides, and the middle section is covered with insulating materials. Sandwich panel has different uses considering the type of middle core. Sandwich panel is used to cover the roof and walls of different places and it is used with different thicknesses.

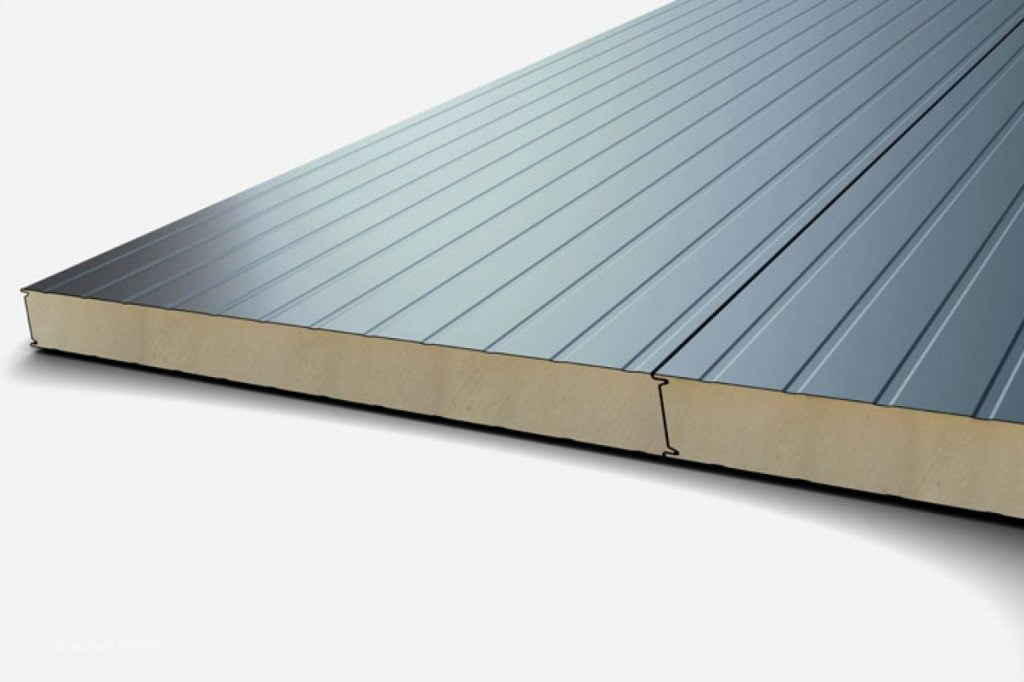

Sandwich wall panel is the most advanced material for covering the walls of the structure. The wall panel is a combination of three layers that are interconnected, the upper and lower layers are covered with sheets, and the middle core is injected with polyurethane foam.

Since these panels are used to cover the wall. It is named as wall sandwich panel. Wall sandwich panels are used to cover shed walls, prefabricated buildings, industrial, office and residential workshops. Wall sandwich panel is used for internal walls and partitions in different projects with defined thickness from 4 to 12 cm.

The structure of sandwich wall panels is designed in such a way that it has an indentation on one side and a protrusion (crotch and tab) on the other side. The reason for this is the result of the panels being fastened together. This overlapping of the edges makes the seam not clear and they are placed seamlessly. Special screws are used to connect wall panels.

Wall panels can withstand loads in heavy volume and high pressure, and paying attention to technical information about the panel leads to better performance of these materials. Different factors are involved in the technical specifications of the wall sandwich panel, including the thickness, weight of the sandwich panel, as well as the characteristics of the types of sheets and types of foam.

Technical specifications of Shiraz wall sandwich panels

The technical specifications of wall sandwich panels include length, width and thickness, which we will mention here.

Minimum length mm | 2000 |

Maximum length mm | According to the customer’s order |

Non-useful width | 120.5 |

Useful width | 118.5 |

Thickness of wall sandwich panels | 5 تا 12.5 centimeter |

Other specifications related to wall sandwich panels including outer layer sheets (sandwich panel sheet) and inner layers (middle foam) will be mentioned in the rest of the article.

The technical specifications of wall sandwich panels depend on components such as color, thickness and material of the sheets used in the relevant structure. The sheets embedded in sandwich wall panels are aluzinc, galvanized or aluminum. The material of the sheets used in the wall sandwich panel varies depending on the metric order and its application, but generally it is produced in two ways, one-sided or two-sided.

Galvanized sheets can be used plain or colored. These sheets are used on one or both sides to make sandwich panels. Aluzinc sheet is a combination of zinc and aluminum alloy steel and a small percentage of silicon, due to its special characteristics, it leads to better quality and useful life of the structure.

Foam sandwich wall panels in Shiraz

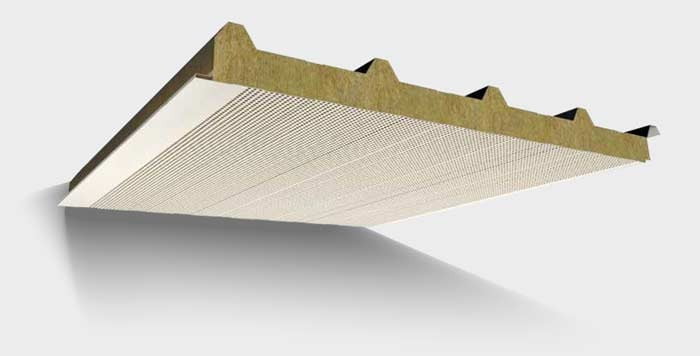

The foam used in the middle layer of the wall sandwich panel has high flexibility and good insulation properties. One of the most widely used foams included in the wall sandwich panel is polyurethane, which adds special properties to the sandwich panel. This foam is initially liquid and then injected between the panels. The way of injection is such that it does not leave any empty space and creates a closed cell structure and prevents energy wastage. Of course, XPS, polystyrene and stone wool insulating foams are used to prepare wall sandwich panels. In addition to the type of insulation, the density or compression is important for sandwich wall panels.

The weight of wall sandwich panels in Shiraz

The weight of the wall panels is one of the components of the technical specifications of the sandwich panel that different factors can affect the weight of the structure. For example, the type of sheet and the thickness of the sheet has a significant effect on the lightness and heaviness of the sheet.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Types of sandwich panels

- Application of sandwich panel in Shiraz, Cold storage above zero in Shiraz, conex Toilets in Shiraz, Dimensions of ceiling sandwich panels in Shiraz, Dimensions of sandwich panels in Shiraz, Feature of sandwich panel in Shiraz, Fixed morgue in Shiraz, Galvanized sandwich panel in Shiraz, Garden shed in Shiraz, Mobile morgue in Shiraz, Resistance of sandwich panel in Shiraz, Shiraz roof sandwich panel, Shiraz sandwich panel, Shiraz sandwich panel density, Shiraz wall sandwich panel, Specifications of sandwich panels in Shiraz, Subzero cold storage in Shiraz, Technical points of sandwich panels in Shiraz, Technical specifications of sandwich panels in Shiraz, The price of a clean room in Shiraz, The price of sandwich panels in Shiraz, The size of the sandwich panel in Shiraz, Types of ceiling sandwich panels in Shiraz, Types of clean rooms in Shiraz, Types of cold storage in Shiraz, Types of sandwich panels in Shiraz, Types of wall sandwich panels in Shiraz, Wall sandwich panel dimensions in Shiraz