Everything you need to know about sandwich wall panels!

In the world of construction and building materials, iron and cement have a strong and important place for many years. Materials that have been used in many ways and have been used in many cases until today. Things that have not been removed even with the advancement of the industry and have been upgraded. In this way, they have been able to gain a good and favorable position for themselves and have many uses in the construction industry.

Despite all the advantages and positive points of these products, there have been many alternatives to traditional building materials. Materials that have more advantages and do not have the defects of previous materials. One of these up-to-date and practical materials in the construction industry is wall sandwich panel. This product is available in different sizes and shapes and has many advantages. In this article, we aim to provide information about this product and everything you need to know about it. Information that will help you get to know a new construction product and ultimately be able to use it better.

Sandwich panel, a prefabricated product

Among all the products that are added to the construction industry market these days, prefabricated products are more popular. Panel sandwiches are also from the same category of products and are considered a prefabricated product. A product that can be used in constructions to speed up the coating and benefit from its benefits. This product has different types, of which the wall type is more useful. Wall sandwich panel, as its name suggests, is installed on the wall and used to cover the walls of a building.

In fact, a sandwich panel can be considered a type of composite that has a sandwich-shaped structure. The product is called sandwich panel for this reason. These wall composites are made in different materials and different sizes and dimensions. In the rest of the article, we will mention more details about this.

Physical characteristics of wall sandwich panels

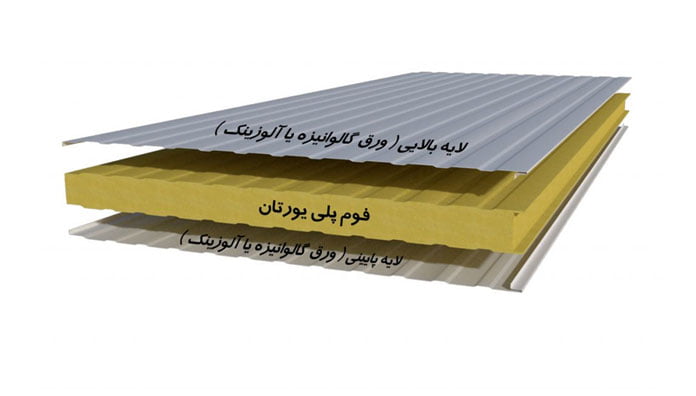

Sandwich wall panel has several different layers that are its constituents. In fact, this product consists of three main layers, two of which (bottom layer and top layer) are made of steel sheet. The layer between these two is the middle core of the sandwich panel, which is used as insulation, and most of the weight of the sandwich panel is related to it.

These three layers are connected to each other and form a complete and integrated structure. The sheets of the bottom layer and on this structure may be of different materials. Materials that are different according to the type of application and usage and can give different characteristics to the built structure. Of course, these said layers are connected to each other using two layers of glue. Two layers of adhesive that are self-insulating and help to increase the strength and resistance of these products, create a proper homogeneity for the product and help to reduce the weight of the product and its uniformity.

Materials of different layers of wall sandwich panels

Wall panel sandwiches can have different materials in different layers. Its upper and lower layers may be made of different alloys and have different characteristics. Its inner and nuclear layer may also have different types and characteristics in some situations.

In many cases, the sandwich panel core is made of stone wool, polyurethane or polystyrene core. The double coating on the bottom and top of the product may be made of steel, aluminum or Alozinc, which is galvanized and of high quality.

The choice between these different sheets completely depends on the conditions and according to what is going to be used and the conditions of the structure and the weather in that city can be different. Stay with us so that we can express some points about these differences and conditions of use of different products.

Selection according to wall sandwich panel applications

As we said, the wall sandwich panel should be chosen according to the application it is supposed to have. For example, the different materials of the under and top covers of the sandwich panel and its inner core and the thickness of the sandwich panel depend on many conditions. There are different types of foam in sandwich wall panels.

The weather, the strength and resistance required, the size of the used space, the amount of heat and heat in the environment, the humidity and dust of the user space and many other things that influence the purchase of wall sandwich panels. You can see some of these items below.

- Wall panel sandwiches with aluminum sheet on the bottom and top have good flexibility and have anti-corrosion properties. Also, they are light weight and suitable for use in large spaces and for a lot of use.

- Galvanized sheets are also light weight and have anti-corrosion properties. They usually have a solid and very strong connection, which makes them a good choice for high-density environments exposed to danger and damage. In fact, this option of practical material has high strength and resistance and light weight.

- Eluzinki sheets are another kind of top and bottom sheets of wall panel sandwiches, which are a combination of aluminum, zinc and silicon. These products usually have a long lifespan and experience very little and limited corrosion and rust. Therefore, they are a good choice for humid areas. Of course, this product itself is also available in the market in two types, light weight and heavy weight.

- The core of this product may also be of different types. Although all materials used in the cores of this product are non-flammable, polyurethane is the best choice for applications at risk of fire, which is very slow-burning and slow to respond to fire. Polyurethane itself is made of Tyren foam or XPS foam, which increase the occurrence of this property in the product.

- Polystyrene is one of the other materials used in the middle core of the wall sandwich panel, which is a good insulator against heat and sound and makes the wall sandwich panel insulated. In addition, it is more economical than other types of sandwich panel cores and causes the price to be reduced to a large extent in large and high dimensions.

- Rock wool is another product that is used in the core of sandwich wall panels. In addition to fire safety and good insulation for heat, this product creates more sound reflection and is known for safety and comfort among sandwich panels. Of course, this product is mostly used in buildings that have a lot of heat and in industries and factories.

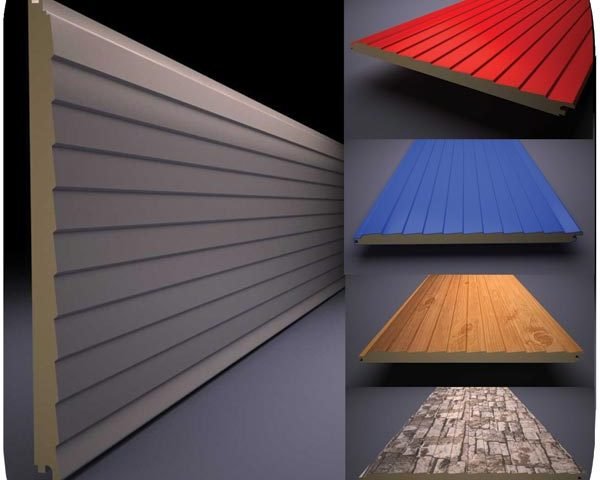

Different models of wall sandwich panels

Wall panel sandwiches are made of different models, each of which has different uses in the construction industry based on their appearance. These different looks and models are:

- Simple wall panel sandwich

- Wall sandwich panel with male and female (different protrusions and depressions)

- Hidden wall screw sandwich panel (having the ability to be screwed and stronger on the wall)

- Lockable wall sandwich panel (with a lock for more protection and safety)

The thickness of the layers of sandwich wall panels

Sandwich wall panels may be made of different and variable thicknesses. Thicknesses, each of which can be used for a specific application and cause a specific feature in the product. These products are available in the market in different thicknesses from 4 to 25 cm, which makes this product versatile.

High-thickness panel sandwiches are used for spaces that need to be insulated, especially against high heat. For example, 8 to 15 cm thick sandwich panels are used for cold stores. Thicker panel sandwiches, about 20 cm thick, are used in the production and construction of freezing tunnels. The lower thicknesses of wall panel sandwiches are used in situations where less weight is required. Especially for large environments and spaces that require a large amount of coverage, it is better to use wall panel sandwiches with less thickness.

20 advantages of using wall sandwich panels

As we said, sandwich wall panel is used these days because of its advantages. The advantages of this product make it suitable for various applications and have more quality and use. It is better to get familiar with these advantages one by one and have information about them before buying this product. In this way, you can use this product in the right place. Below are some of the benefits of using this product. It is hoped that by reading these advantages and tips, you can make a good and suitable choice for yourself.

- Less weight and lighter than traditional structures

- Very easy and fast delivery and installation

- Reasonable and economical price

- Saves energy consumption and increases energy efficiency

- High and lasting structural strength

- Suitable and resistant quality and making the structure stable

- High flexibility in dealing with other structures

- Resistant to tensile and compression forces

- Insulation against sound

- Non-passage of cold and heat and insulation against energy

- Long lasting for years

- The possibility of connection after the construction of the building and structure

- Being fireproof and creating safety and security against fire

- Prevent rain and dust penetration

- Not being eaten by insects and vermin

- Considerable tolerance of load pressure

- Simple and convenient adhesion of foam to the sheet

- Chemical resistance

- Resistance to wet weather and humidity

- The possibility of cleaning the panel and its hygiene for sterilized environments

Application of wall sandwich panel

Because of all the advantages that we have said, sandwich panels have many audiences these days and are used in different applications. This product can be considered as a structure that can be used for any type of use. However, these days sandwich panel is used more than any other in industrial centers, factories and stores.

This use is more than anything due to the simple construction and simple and convenient installation of these panels. In fact, connecting these structures is so simple and convenient that people can install it on the wall without any help. This issue has caused many built buildings and sheds to use wall sandwich panels to cover their walls. Sports sheds, industrial workshops, large and commercial stores and many factories use this product in the type of covering of their buildings and use its benefits.

Summary of final points

As you have read in this article and so far, sandwich wall panel is one of the practical products in the construction industry today. With its entry into the market, this new product has been able to be a suitable alternative to other traditional construction products. Products that have been used for years now have nothing to say about the benefits of this product. These days, sandwich wall panel is one of the most diverse and widely used products in various construction industries. A product that we discussed in this article completely and comprehensively and shared information about it.

After explaining what and how the wall sandwich panel works, we talked about the layers and materials of this product and explained the different types of materials used in its different types. After that, we made some points about the use of this product and talked about the materials used according to the application that is used. In the end, we felt it necessary to talk about the advantages of using sandwich panels instead of traditional products available in the market and to consider the thickness and different models of this product. We hope that you have accompanied us so far in this article and now you have been able to get accurate and complete information about it. Information that will help you make the right purchase.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Polystyrene sandwich panel, Types of sandwich panels, Wall sandwich panel

- Buy ceiling sandwich panels in Shiraz, Buy sandwich panels in Shiraz, Buy sandwich wall panels in Shiraz, Buying a clean room in Shiraz, Buying a cold store in Shiraz, Installation of ceiling sandwich panels in Shiraz, Installation of sandwich panels in Shiraz, Installation of wall sandwich panels in Shiraz, Roof sandwich panel in Shiraz, Roof sandwich panel installer in Shiraz, Sandwich panel, Sandwich panel in Shiraz, Sandwich panel installer in Shiraz, Sandwich panel production method in Shiraz, Sandwich wall panel in Iran, Sandwich wall panel in Shiraz, Selling ceiling sandwich panels in Shiraz, Selling sandwich panels in Shiraz, Selling wall sandwich panels in Shiraz, The price of ceiling sandwich panel in Shiraz, The price of sandwich panels in Shiraz, The price of wall sandwich panels in Shiraz, Types of sandwich panels, Types of sandwich panels in Iran, Wall sandwich panel, Wall sandwich panel installer in Shiraz