Wall and ceiling sandwich panel price in Isfahan

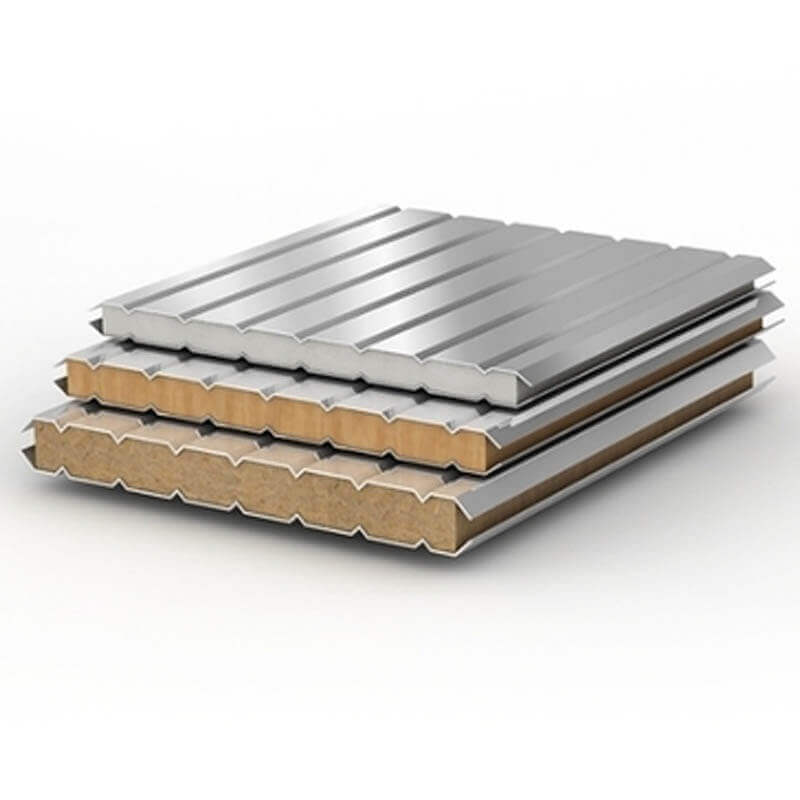

Isfahan sandwich panels are composite materials that are formed by connecting two thin and strong layers from the top and bottom to the middle core which is very light but thick. The thick middle core is equal to the surface layers, which has a specific density of 40+_2 kg. The layers located on the sides of the panel are made of stainless steel. It is very thin and hard, which is completely resistant to decay and rust. Due to the material used, the structure is lightweight and flexible.

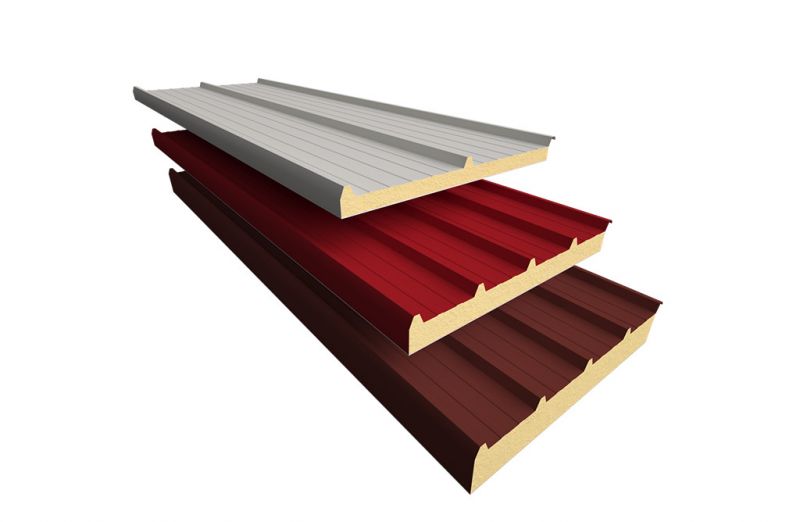

The quality of sandwich panels depends on the composition of surface materials, the shape and type of materials used in the middle layer. The material of the sheets used in the panel can be made of aluzinc, galvanized or aluminum, each of which adds special features to the panel. The middle core is covered with polyurethane foam, which makes sandwich panels completely resistant to heat, cold, sound, and moisture due to its unique features.

Sandwich panels are often designed as a round sheet and are produced in single-sheet, single-foil, single-sheet, nylon, double-foil, and single-paper models.

Due to the variety of panels, due to the presence of sheets, it should be considered that the sheet has a great impact on the quality, durability and life of sandwich panels. The strength of sandwich panels is due to the presence of a core in the middle layer and the transfer of power from one layer to another layer. In general, sandwich panels are divided into wall and ceiling categories.

Ceiling and wall sandwich panels in Isfahan

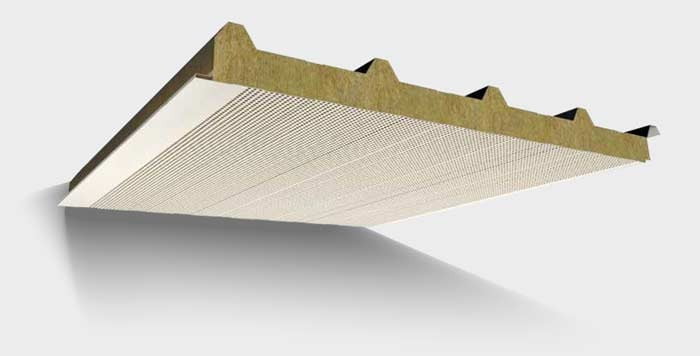

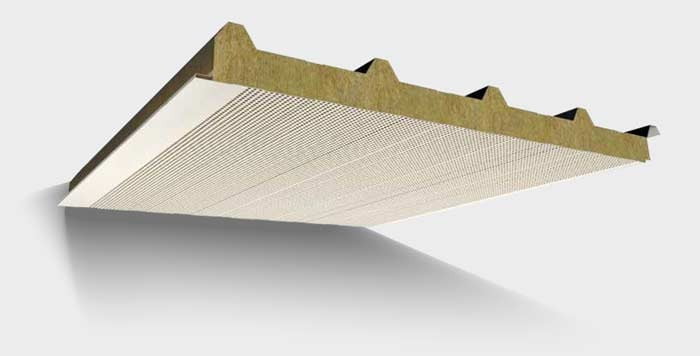

As its name suggests, the roof sandwich panel is used for the construction of the roof. Of course, we should not forget that the most important part of a roof structure is that strong materials should be used. The level of resistance and strength of the roof depends on the material used. The ceiling sandwich panel has a step on the surface, which is essential. The less number of steps the sandwich panel has, the higher its weight bearing capacity.

In the previous articles, we discussed in detail about the ceiling sandwich panel and its applications.

Wall sandwich panel is one of the most widely used types of these products, which is used to build structural walls. Wall sandwich panel is designed in various types of crotch, tongue and hidden screw. Currently, the best type of sheet for making sandwich panels is Alozinc, but unfortunately it is not produced in our country.

However, sandwich panels are produced with galvanized sheets, which are of high quality. It should be noted that if the sheet used is not of good quality, after some time the panels will rot and rust and as a result they need to be replaced. The foam used in the middle layer is covered with polyurethane, polystyrene, xps, or stone wool and glass wool. Each adds specific features to the panel. Polyurethane materials are completely safe against heat, cold, sound, and fire, which prevents the exchange of energy between the outside and the inside environment.

The greater the thickness of the middle layer, the more sound and thermal insulation it will be, and this thickness varies between 4 and 25 cm. The type of foam used in making sandwich panels has a significant impact on the quality of the final product. The best material for production is polyurethane, which has better quality than other similar products.

The first point to buy a sandwich panel is to check and pay attention to the type of brand. Currently, many factories in the country are producing products, one of the most important of which is Kimia Panel. You can contact the listed numbers or the website to get the necessary information.

One of the essential points for ordering the product is to check the thickness of the panel. If you want the panel to have sufficient quality and strength. The appropriate thickness should be considered. The required thickness should be asked from the manufacturer or sales experts and then purchase.

One of the features of the quality panel is the sheet cover, which is quickly damaged and does not have enough strength if the right material is not used. The density of intermediate materials has a great influence on the weight of the panel and the strength of the structure, so special attention should be paid when purchasing. In general, the price of sandwich panel is determined in terms of square meters, which depends on various indicators.

The most important factors are panel type, sheet thickness, panel design, insulation type and density level.

Weight of sandwich panel = (density of bottom layer*thickness)+(density of middle insulation*thickness)+density of top sheet*thickness)*length*width

Sandwich panels generally have a light weight structure, but with the presence of these factors, the weights vary.

To view the products, you can refer to the image gallery.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Polyurethane sandwich panel, Types of sandwich panels

- Buy sandwich panel in Isfahan, Buy wall sandwich panels in Isfahan, Buying and selling sandwich panels in Isfahan, Buying ceiling sandwich panels in Isfahan, Ceiling sandwich panel installer in Isfahan, Installation of ceiling sandwich panels in Isfahan, Installation of sandwich panels in Isfahan, Kimia Panel factory in Shiraz, Price of ceiling sandwich panel in Isfahan, Roof sandwich panel in Isfahan, Sale of ceiling sandwich panels in Isfahan, Sandwich panel in Isfahan, Sandwich panel installer in Isfahan, Sandwich panel price in Isfahan, Sandwich panel sales agent in Isfahan, Sandwich wall panel in Isfahan, Selling sandwich panels in Isfahan, Selling wall sandwich panels in Isfahan, Wall sandwich panel installer in Isfahan, Wall sandwich panel price in Isfahan