Today, sandwich panel has been highly regarded by engineers and architects. The main reason and its effective use is the good feedback of the insulation foam in the middle core and easy installation in a short period of time.

What is the structure of sandwich panel?

The middle core of these panels is polyurethane or polystyrene foam, which is surrounded on both sides by galvanized, aluzinc, or aluminum sheets. These panels are very practical structures. which can be seen in all kinds of wall panels, ceiling panels, clean rooms, poultry houses.

Important factors that make sandwich panels superior to other structures.

1) The reasonable price of sandwich panel compared to other structures

the components of sandwich panel are very light and cheap compared to other materials. This is an important factor for more sales and its use in building structures. Kimia Panel Company It is in the manufacturing and production of all kinds of sandwich panels with polyurethane or polystyrene insulation with high standards and reasonable prices.

2) The diversity of sandwich applications for all types of structures

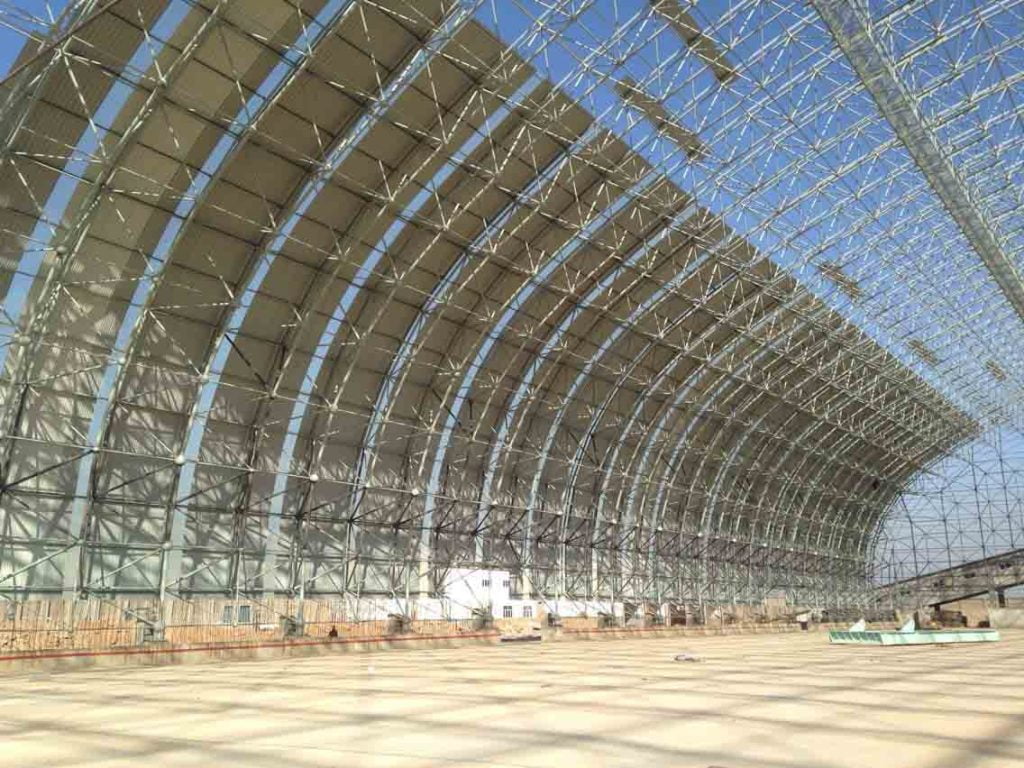

Due to the wide variety of these panels, they are widely used in the construction of all types of structures, including cold storages, chicken farms, agriculture, animal husbandry, airplane hangar, residential… Another type of decorative sandwich panel is May it be used in most of the facades of structures, office buildings, residential buildings, commercial buildings, and because of its special ability, it has received good feedback and is widely used.

3) The resistance of sandwich panel against fire

due to the presence of polyurethane, polystyrene or stone wool insulation foam in the middle core of sandwich panel, it is suitable for fire insulation. This insulation is slow-burning and highly resistant to fire. Therefore, most people use these sandwich panels to build buildings. If this panel is placed in front of the fire, it can withstand the temperature of 1000 degrees Celsius, and it creates a suitable safety for the construction of the structure, and another characteristic of these structures is that it does not change color in front of the sunlight.

4) Light weight of the panels and easy portability

sandwich panels are cut in different dimensions and sizes according to the customer’s needs and can be cut from 2 to 15 meters in length and can be easily transported by trailer. Because polyurethane foam is used in the structure of this panel, it thickens the texture and is very light in terms of weight. This type of material saves time and money.

5) Sandwich panel with variety of designs and different colors

different colors can be used in the design and construction of these structures and there is no limit for this work, these colors are of the furnace type and against corrosion and decay And even the sunlight is very resistant. Usually white colors work, but yellow, orange, and red colors can also be used for the roof of structures.

6) Minimizing energy and time consumption

sandwich panels can be easily moved and installed due to their light weight. This structure can be opened and closed if needed, which is better done by experienced and specialized people.

7) Proper insulation

one of the best features of sandwich foam is insulation, which is very practical and is embedded in its middle core, and is an important factor in preventing sound, heat, heat, and cold from entering the panel, and it is used for walls. and the roof of shed structures and food storages and poultry houses.

8) Washing ability

White color is usually used in the construction of sandwich panels, but there is no limit for colors. For washing, you should pay attention to the type of paint used and choose the type of detergent. The performance of these detergents is very effective on the color of the panels, and it is better not to use acids, for this reason, the most effective option is to build a clean room with the same smooth panels without indentation, which will be less contaminated.

9) The stability of sandwich panels against solvents

sandwich panels are resistant to many solvents and are resistant even to harsh, rainy and windy weather conditions, and their quality does not decrease, and even against the penetration of insects. And it also prevents rodents.

Kimia Panel Company has started its activity in the field of producing all kinds of ceiling and wall sandwich panels since 1400, and relying on 20 years of useful experience in producing all kinds of industrial refrigerators and cooling equipment in the form of refrigeration industries, and since then until Relying on the quality of our agenda, Kanon has put customer satisfaction at the top of his work so that while improving and progressing, meeting the demands of customers can create a better position in this field.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Anti-acid sandwich panel, Decorative sandwich panel, Duct panel, Fireproof sandwich panel, Polystyrene sandwich panel, Polyurethane sandwich panel, Roof sandwich panel, Types of sandwich panels, Wall sandwich panel

- 3d panel, Buy sandwich panels in Shiraz, Buy sandwich wall panels in Shiraz, Buying sandwich panels in Iran, Installation of ceiling sandwich panels in Shiraz, Installation of sandwich panels in Iran, Kimia Panel factory in Shiraz, Roof sandwich panel in Shiraz, Sandwich wall panel in Shiraz, The price of ceiling sandwich panel in Shiraz, The price of sandwich panels in Iran, The price of wall sandwich panels in Shiraz, The superiority of sandwich panels over other structures, Types of sandwich panels in Iran, Types of sandwich panels in Shiraz, Wall sandwich panel installer in Shiraz