Sandwich panel, which is also known as sandwich panel, is one of the important building components that has an important application. Sandwich panel is actually prepared and used in a prefabricated way and it is made in different types. Among the applications, it can be mentioned to be used on the roof, wall, cold house, warehouse, etc. Stay with us until the end of the article to get more information about the sandwich panel and its installation.

What is a sandwich panel?

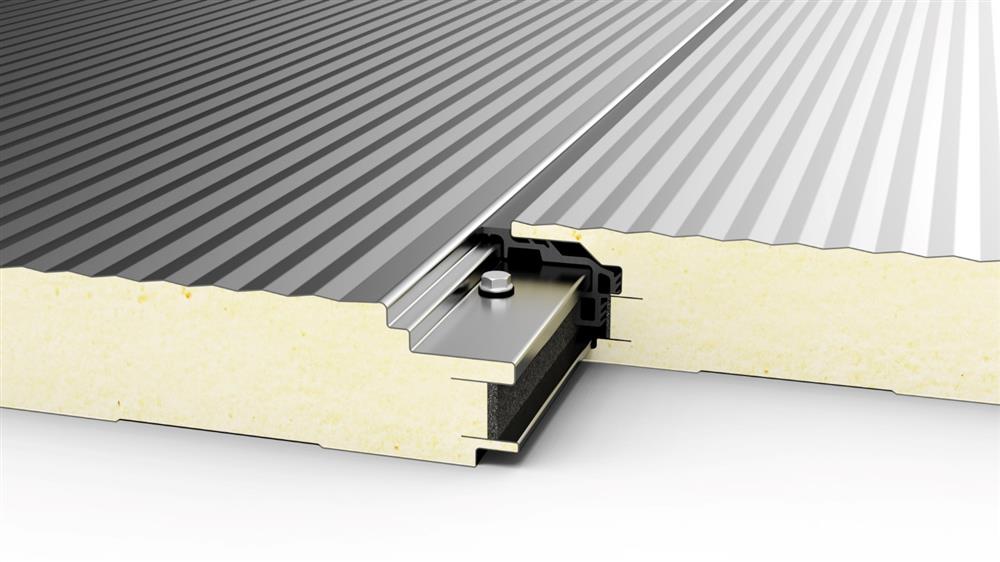

In fact, sandwich panels can be considered materials that can be used as a substitute for traditional materials. Sandwich panel is made using raw materials such as stainless steel, galvanized sheet, aluzinc, copper, etc., using new and advanced technologies and in three layers. Sandwich panel layers are: top layer, insulation layer and bottom layer. The insulating layer of the sandwich panel, which is actually its middle layer, It is made using materials that have insulating properties and of course are light in weight. Among these materials, we can mention stone wool, glass wool, polyurethane, etc. The upper and sole layers, which cover both sides of the insulating layer, are made of metal sheets such as galvanized, aluminum, etc.

Sandwich panel installation:

Regarding the sandwich panel, in addition to its quality, its correct installation is also very important. Because if it is not installed correctly, we have to wait for the upcoming problems. To install a sandwich panel, we need a series of tools and installation steps, which we will cover.

Tools required for sandwich panel installation:

- Sandwich panel machine: This machine is used for the purpose of cutting sandwich panels. Among the components of this important and widely used device, we can mention a compass and a hand saw. In addition to this device, a file is also used, which is used in case of unevenness after cutting.

- Sandwich panel insulation glue: These glues are known as mastic glue. These adhesives can cover and connect the seams and gaps between sandwich panels with their high adhesive power. One of the advantages of these adhesives is their resistance and non-change in different temperatures.

- Galvanized screws with washers: These screws are used to fix sandwich panels to each other. Self-tapping screws are made in different sizes to be used in different conditions.

- Industrial hair dryer: Industrial hair dryers are used in cases where we need to remove coating, remove paint, or dry and heat pipes. The amount of air coming out of this device is adjustable and can be controlled according to the need.

- Sandwich panel saw: This tool is used to cut different sandwich panels to different dimensions and according to needs.

- Polyurethane foam: Polyurethane foam is a tool used to connect sandwich panels together.

- Wire cutting scissors: Wire cutting scissors, following its name, are suitable for cutting wire, screws, rebar and metals. The quality of wire cutting scissors has a direct effect on the accuracy of the cutting process.

- Knotting device: This device is used to tie mesh networks in the sandwich panel installation process.

- Skilled sandwich panel installers can be considered as the most important component for sandwich panel installation. Leaving sandwich panel installation to unskilled installers can waste the best quality of sandwich panel and the best tools.

How to install a sandwich panel?

If you want to do the sandwich panel installation process correctly, you must first transport them correctly and without damage. You should be careful to place the sandwich panels in the closest and at the same time the safest place near the installation, so that they need to be moved less. To transport the sandwich panel, you must be careful to hold the bottom and top layers (metal layers) correctly so as not to cause the layers to break apart. In addition, if you intend to transport a large volume of sandwich panels, pack them properly and prevent damage caused by friction between them.

Regarding the columns and bases, you must ensure that each one is in the designated position and installed correctly. Otherwise, you should not expect a strong and resistant structure.

It is necessary to pay attention to creating or not creating a right angle between the sandwich panels with the horizontal surface in the process of installing sandwich panels. Also, for the sandwich panels to be sealed, it is necessary that the surfaces of the joint do not have any dust, moisture, etc.

How to install a ceiling sandwich panel:

Installation of roof sandwich panel requires substructure, so the roof covering should be taken into consideration. To install sandwich panels, they need to be placed on the underlying roof panels. In this process, one galvanized screw is also used for every square meter that the sandwich panel is installed. Also, this process requires sealing, which is explained below.

How to install a wall sandwich panel:

We also need a substructure to install wall sandwich panels. Also, a strong support made of iron profiles is used, which is done before installing the wall sandwich panel. In this regard, it is interesting to know that although these sandwich panels themselves have the ability to insulate, special adhesives are used to intensify this ability. In this case, we will also need sealing.

How to seal the sandwich panel:

First of all, it should be known that the purpose of sealing is to properly connect the plates together. Therefore, the male or female of each must be determined first. Also, the joints of the sandwich panels are covered with polyurethane spray before being connected, and the sandwich panels are connected together before it is inflated. In fact, without sealing the sandwich panels, you cannot be sure of their proper connection and strength.

What are the advantages of sandwich panels?

Sandwich panel is one of the building materials that is made using modern technologies and has many advantages, which are:

1- Quick and easy installation: since the sandwich panel is easily installed and its installation is done quickly, you will get rid of some troubles and save time.

2- Possibility of assembly and disassembly and relocation: this feature of sandwich panels allows you to use them again later.

3- Cost of proper preparation and maintenance: sandwich panels are materials that, in addition to their benefits and applications, also have an affordable price. In addition, the cost of maintenance and care of the sandwich panel is also appropriate.

4- Ease of transportation: since the sandwich panel is one of the light weight materials, its transportation is done easily.

5- Resistance to external damage: Sandwich panel has a durable and stable structure and resists damage caused by moisture, fire, rust, etc.

6- Washability: Another advantage of the sandwich panel is its washability, which facilitates its cleanliness.

7- Durability and long life: it is resistant to rust, corrosion, decay, etc., which makes it durable and long life.

8- Proper insulation: As we said, the middle layer of the sandwich panel is made using materials with insulating characteristics. Therefore, the sandwich panel can insulate against cold, heat, moisture and even sound and save energy consumption. Also, due to the sandwich panel’s sound insulation feature, it prevents the internal sounds of the building from going out and external sounds from entering the building.

9- Stability against earthquakes: this characteristic of sandwich panels is due to their light weight.

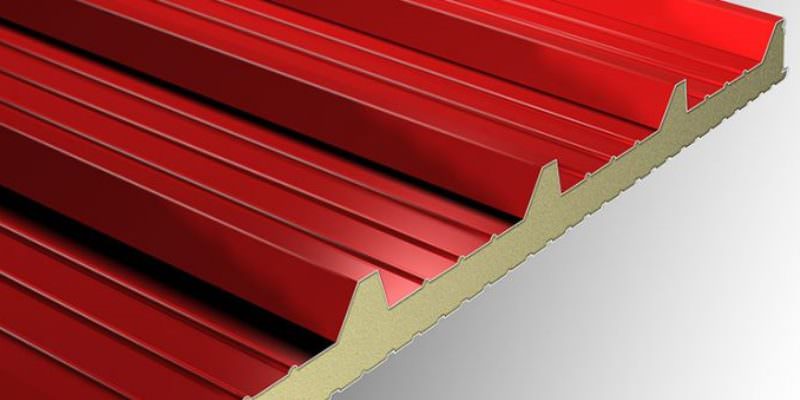

10- Variety: As we said, sandwich panel is produced and supplied in different types. In addition, these practical materials are also diverse in terms of design and color.

11- High strength: sandwich panel has high resistance against impact, pressure, etc. Also, complementing their depressions and projections increases their strength.

12- Resistant to the growth of plants and the entry of insects: the sandwich panel has the ability to prevent the growth of plants such as moss, as well as the entry of harmful insects into the building.

13- Compatibility with health: If you are worried about the chemical and annoying smell of these materials, don’t worry at all because these materials are completely odorless. They are also completely reliable in terms of compatibility with human and animal health.

Disadvantages of sandwich panels:

As mentioned at the beginning of the article, there are different types of sandwich panels, which we will describe in this section:

- Roof sandwich panel: According to the name of this type of sandwich panel, its application is in roof covering. Roof sandwich panel, like other types of sandwich panel, is produced in three layers. The construction of the roof of many environments, such as stadiums, rooms, condos, industrial buildings, etc., is done using the type of sandwich panels. It should be noted that the raw materials used for the production of ceiling sandwich panels have higher quality, resistance, strength, durability and longevity.

- Wall sandwich panel: The wall sandwich panel, in terms of structure, is relatively similar to the ceiling sandwich panel, but its application is in the wall of different structures.

- Polyurethane sandwich panel: Polyurethane is used in the middle layer or insulation layer of this type of sandwich panel. One of the features of this type of sandwich panel is its high insulation power against heat and sound. This sandwich panel is also resistant to moisture and the growth of destructive plants, and this is a proof of its suitability for use in humid environments such as the north of the country.

- Polystyrene sandwich panel: The material used in the middle layer of this type of sandwich panel is polystyrene, which provides less insulation than other types of sandwich panels. Another feature of this type of sandwich panel is its light weight. At the same time, the price of this type of sandwich panel is also low.

- Rock wool sandwich panel: Sandwich panels that use rock wool in their insulation layer have a high ability to resist fire and fire and will be suitable in environments where there is a possibility of fire.

- Aluzinc sheet sandwich panel: The top and bottom layers of this type of sandwich panel are made with a combination of aluminum, zinc and galvanized metals, and the combination of these metals is called aluzinc. One of the characteristics of Alozinc is its flexibility as well as its ability to be dyed and welded. This type of sandwich panel is produced and supplied in different designs.

Sandwich panel with galvanized sheet: This type of sandwich panel is highly resistant to various factors, including corrosion.

Aluminum sandwich panel: sandwich panels whose upper and lower layers are made of aluminum sheet, are light in weight and have an affordable price. This type of sandwich panel has good compatibility with different climates and has high resistance.

Last word:

Sandwich panels are light and practical materials that are used to cover the roof and wall and are made in different types. The installation of these materials is an important issue that is explained in this article along with its features and what it is.To view videos, you can refer to Aparat channel.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Polystyrene sandwich panel, Polyurethane sandwich panel, Roof sandwich panel, sandwich panel xps, Types of sandwich panels, Wall sandwich panel

- Buy ceiling sandwich panels in Shiraz, Buy sandwich panels in Shiraz, Buy sandwich wall panels in Shiraz, Cold storage sandwich panel in Shiraz, Installation of ceiling sandwich panels in Shiraz, Installation of sandwich panels in Shiraz, Installation of wall sandwich panels in Shiraz, Kimia Panel factory in Shiraz, Neat sataq sandwich panel in Shiraz, Roof sandwich panel, Roof sandwich panel in Shiraz, Roof sandwich panel installer in Shiraz, Sandwich panel, Sandwich panel in Shiraz, Sandwich panel installer in Shiraz, Sandwich wall panel in Iran, Sandwich wall panel in Shiraz, Selling ceiling sandwich panels in Shiraz, Selling sandwich panels in Shiraz, Selling wall sandwich panels in Shiraz, The price of ceiling sandwich panel in Shiraz, The price of sandwich panels in Shiraz, The price of wall sandwich panels in Shiraz, Types of sandwich panels, Types of sandwich panels in Iran, Wall sandwich panel installer in Shiraz