Familiarity with flushing in Iran

In this article, we will examine what it is, definition, types, benefits and even problems of sandwich panel flushing. At first, the name or its use may seem strange and unnecessary to you, but as soon as it is explained, you will understand that sandwich panel flushing has a wide and common use in today’s world.

What is sandwich panel flushing?

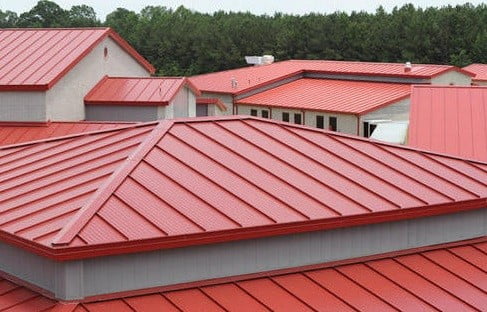

Flushing sandwich panel means a sheet that covers the seams and open spaces between sandwich panels. Flushing sandwich panel is the same as gutter sheet. You must have seen the thick sloping sheets installed on the roofs and walls of buildings or even the roof of the premises, but you probably never paid attention to the necessity of their presence and installation.

You might think that a blocked and damaged roof is a minor problem and that it won’t hurt to ignore it. But if such a roof is not repaired, it can cause more costly damage. Examples of damage often caused by inefficient gutters or roofs include wet foundations, rotting soles, damaged brickwork, and more.

There is a wide range of gutter accessories that are an effective solution for new and renovation projects. Sandwich panel flashing is exactly one such flashing accessory that improves the quality and performance of the roof and is made from a variety of proven materials such as lightweight plastic and hardened metal.

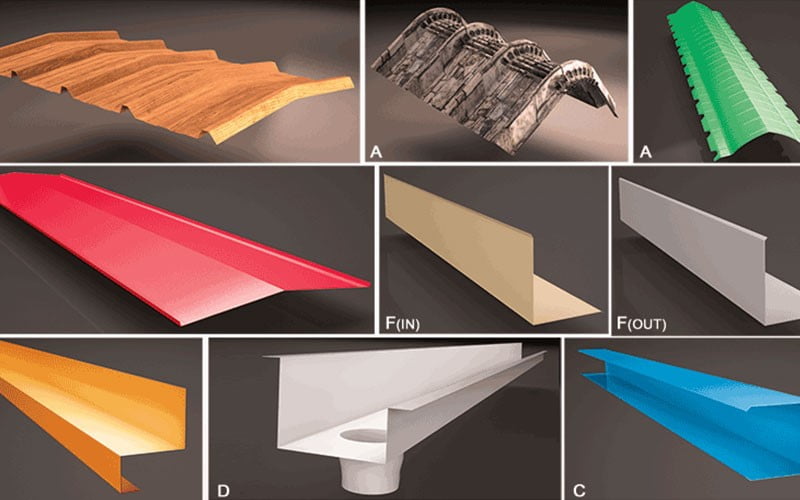

There are many reasons for installing these flushes, but in general, there are two types of flushes: ceiling and wall, both of which are installed for similar purposes. Flushing or gutter sheets are also installed to beautify and enhance the appearance of buildings. These sloping sheets are available in various designs and types according to your taste, which you can use to give a more beautiful look to your building.

But in general, flashings are installed in the first place to create a seal, air seal and dust seal. Because it doesn’t matter what field your building is in, it can be residential or office or even commercial, anyway, moisture and pollutants tend to pass through the seams and cracks regardless of the type of building, so sandwich panel flushing is very widely used in construction. And it plays the role of covering ten.

Positive effects of sandwich panel flushing

A rainwater retention system plays an important role in both residential and commercial properties. Examples of the benefits and positive effects of this system include:

It prevents the accumulation of moisture in the foundations of your property, which causes an increase in humidity.

Prevents the entry of any pollutants, moisture and water.

Prevents rapid flow of water from damaged brickwork and any exterior masonry.

It prevents soil erosion and damage to plants next to the desired building.

It reduces the possibility of overflows caused by ice dams, blocked roofs and other obstructions.

Metal panels are usually available with a full range of accessories, including flashings (in any color, including the color of the panel) and a variety of fasteners to mount the panels on any substrate (steel, reinforced concrete or wood).

The material is easy to process, so buildings can be designed with windows and doors wherever needed.

Sandwich panel with polyurethane core

Polyurethane is the best and most common thermal insulation material available in the market. After years of dominating the market with older materials, such as mineral wool or EPS, better alternatives have emerged in the residential construction market today in the form of panels made of rigid polyurethane foam, Thermano. The potential to save space inside the building is one of the obvious benefits of this type of panel.

Of course, the higher-quality thermal insulation of the panels has a smaller wall thickness than other types of cores and at the same time maintains the same thermal insulation parameters. Another very important advantage is the lower density of the material from which the core is made. This factor significantly eases the installation process because no special tools or equipment will be needed at the project site.

Sandwich panel with mineral wool core

This type has two advantages:

_Sound insulation efficiency

_ Resistance to fire

One of the characteristics of mineral wools is having a partition designed to prevent excessive sound transmission. The best versions of the panel have a sound insulation feature, which in practice becomes a sound insulation effect up to 33 dB. Another important feature is their behavior in fire. In fact, it means that both the sealing and the fire rating of the partition are maintained for a sufficient period of time. This is enough time to get out of the building safely and also to minimize possible damages caused by fire.

Sandwich panel with EPS core

Today, this type of core has been replaced with mineral wool and polyurethane. Comparing all three types of panels, it should be noted that EPS is between mineral wool and polyurethane in terms of thermal insulation properties; But in response to fire, it is lower than mineral wool.

Of course, keep in mind that the performance of these panels in any field and for any form of application, regardless of its type, depends on the quality of your sandwich panel to ensure your safety and comfort.

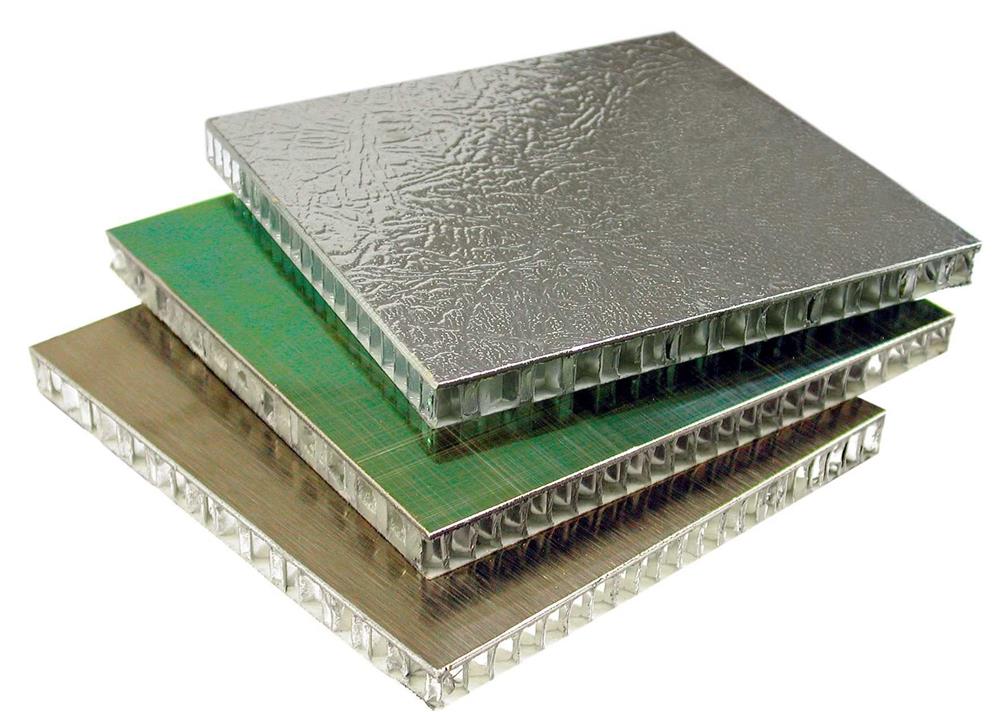

Sandwich panel or gutter sheet

We said that sandwich panel is used as a functional product for covering the walls and roof of buildings. Each panel has a core or center with the content of thermal insulation material, which is covered on both sides with metal sheet. Sandwich panels are not structural materials, so you don’t necessarily need them in construction, but these flashings are needed by people during business activities and climatic conditions. Structural forces are carried by the steel structure or other supporting frame to which the panels are attached.

Types of sandwich panels

The types of sandwich panels are generally grouped based on the thermal insulation materials used and used in them as a structural core. Sandwich panels with cores of EPS or expanded polystyrene, mineral wool and polyurethane meaning PIR or polyisocyanurate are most often found and all of them can be installed with ease.

The mentioned types mainly have different and unique performance in terms of thermal insulation performance, sound insulation performance, reaction to fire and weight.

Why should you use a sandwich panel?

Sandwich panels have many advantages, which in general, the advantages related to its cost and price are widely appreciated. A comparison between frame technology, meaning frames covered with sandwich panels, and traditional building technologies based on masonry walls demonstrates the advantages of sandwich panels in three key areas:

Direct costs

Constructing a building in each of these technologies requires similar levels of capital expenditure. In this context, the comparison includes the costs of construction materials, labor and transportation.

Construction time

Completing a building based on the traditional masonry process may take six to seven months. The construction process of a building of the same volume using sandwich panel flashing takes only one month to complete.

It is quite clear and predictable that the timing of the construction is considered a very important factor in the line of business. So, the sooner a building or production warehouse is up and running, the faster the return on investment can be achieved.

Buildings with flashing are assembled instead of a process called construction. Finished structural parts and cladding components arrive at the desired location and are then assembled similar to a toy brick house. Another feature is that there is no need to wait for the building shell to lose excess moisture.

Construction processes

In some parts of the industry, construction requirements can be critical to a construction project. Flushing installation is a dry process that does not require the presence of building materials. Of course, it only requires assembling the structure and fixing the cover along with the panels, as well as the presence of bolts and nuts.

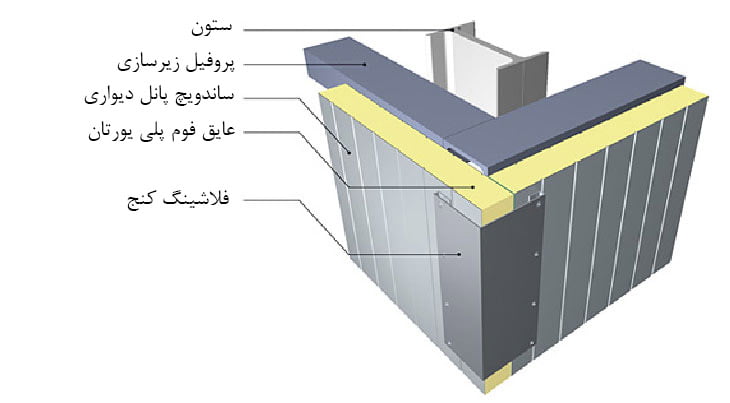

How is the sandwich panel installed on the wall or ceiling?

Perhaps one of the main reasons for the popularity and common use of sandwich panels is their ease of installation. So that we can give this assurance to people who like to install flashing but hate the hassle and hassle of working with materials, sandwich panels are installed easily and in the shortest possible time. Estimates and experiences estimate that installing 600 square meters of gutter sheets takes approximately 8 hours for an expert and skilled construction worker.

The wall and ceiling sandwich panel installation process is as follows:

The required building materials are delivered to the installation site. These materials include sandwich panels, subframe components (cold-formed) and accessories (including flashing, fasteners, washers, bolts, etc.). Balex Metal (Construction Projects Equipment) provides all the components needed to complete the installation process.

Assembled subframes are installed along with beams, columns and purlins. Sandwich panels are fastened to the structural components under the frame by appropriate fasteners. The joints between sandwich panels are sealed and flashing is installed.

How many screws are needed to close the sandwich panel?

This question is one of the most common questions asked by clients and panel users during the project preparation phase. The answer to this common question can be approximated, but it really depends on you and your sensibilities. In such a way that it is placed in approximately every 1.1 fasteners per square meter of sandwich panel. Of course, as a rule, the actual number, distance and arrangement depends on the decision of the project designer or supplier of building materials. Of course, if you are a panel installer for a small area, we must say that these things are closed to the opinion of the building owner and your own technical opinion.

Sandwich panels can be used in all kinds of structures. When it comes to variety, your imagination is limited to what you have heard and seen. While sandwich panels are even generally used in industrial applications! Some huge housing projects also use flashing and sandwich panels.

Due to the short time in installation and covering of the unit and large scale, sandwich panels are the most popular in the construction and application of the majority of buildings.

Do sandwich panels have any problems?

Polystyrene and polyethylene soften and begin to melt at about 93.3°C. As a result, there is a great risk of fire from these two materials.

How can builders reduce the risks of sandwich panel flashing in construction?

To explain this purpose, take seriously the recommendations we offer:

Use sandwich panels with non-combustible insulation. Doing so is effective in minimizing smoke pollution and is especially important in commercial buildings that require quality control and air conditioning, such as food processing and pharmaceutical plants. The use of non-combustible materials in the interior walls can also create a protective layer.

Do not perform dangerous actions near the walls. To avoid accidental ignition sources such as welding, cooking, recharging forklift batteries and spray painting, do this at a distance.

Enclose all electricity passing through the walls and ceiling in metal. Make sure all sandwich panels are properly sealed and there is no exposed combustible insulation.

Avoid storing combustible materials along the exterior walls of the building. Smoking should not be used inside buildings that have combustible sandwich panels.

Conclusion

We are sure that by following this line of the article, you have easily realized the many advantages of sandwich panel flashing over its disadvantages, one of these advantages being inexpensive insulation that is easy to install. Of course, sandwich panels that are made of combustible materials will cause serious damage and danger in case of fire. That’s why, if possible, it’s important to talk to the panel manufacturer or installer about the materials being used to learn about the potential dangers of sandwich panel flashing.In the following, you can see Kimia Panel’s Instagram page.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Anti-acid sandwich panel, clean room, Cold room sandwich panel, conex, Decorative sandwich panel, Fireproof sandwich panel, Group conex, Guard conex, Management conex, Office conex, other products, Polystyrene sandwich panel, Polyurethane sandwich panel, Roof sandwich panel, sandwich panel xps, Soundproof sandwich panel, Standard conex, Steel deck, Toilet conex, Types of sandwich panels, Villa conex, Wall sandwich panel

- Buy ceiling sandwich panels in Shiraz, Buy sandwich panels in Shiraz, Buy sandwich wall panels in Shiraz, Buying flushing in Shiraz, Flushing, Flushing sales in Shiraz, Flushing U in Shiraz, Installation of ceiling sandwich panels in Shiraz, Installation of flushing in Shiraz, Installation of sandwich panels in Shiraz, Installation of wall sandwich panels in Shiraz, Kimia Panel factory in Shiraz, Roof sandwich panel in Shiraz, Roof sandwich panel installer in Shiraz, Sandwich panel in Shiraz, Sandwich panel installer in Shiraz, Sandwich wall panel in Shiraz, Selling ceiling sandwich panels in Shiraz, Selling sandwich panels in Shiraz, Selling wall sandwich panels in Shiraz, The price of flushing in Shiraz, The price of sandwich panels in Shiraz, The price of wall sandwich panels in Shiraz, Types of flushing, Types of flushing in Iran, Types of flushing in Shiraz, Types of sandwich panels in Iran, Wall sandwich panel installer in Shiraz