Buying cold meat in Iran

One of the most common methods of preserving meat for a short or long period of time is chilling or freezing. The cold and freezing process must be done in special conditions and at the right temperature. Protein materials such as red meat, chicken and fish due to their high consumption which they have, must be kept in special conditions, because in case of failure in this matter, the health and hygiene of the product will decrease and the quality of the product will decrease and it will spoil the meat. Creating an environment with the right temperature and sufficient humidity is one of the most basic principles of storage. This is the product. In this article, we are going to introduce you to cold storage for meat and its types.

Meat storage cold storage

The best way to preserve meat is to chill. The new process used to chill meat is called super-chilling, in which the temperature of the meat is quickly reduced to the nearest freezing point and then stored a little above the freezing point. Cooling should be done quickly because the mesophilic microorganisms will have little chance to grow. Immediately after killing, the internal temperature of the carcass is about 38 degrees Celsius. After death, it increases to 40 degrees due to the interactions that take place This is the reason why the carcass should be refrigerated after slaughter so that microorganisms do not have a chance to grow.

In the pre-cooling halls of the meat slaughterhouse, by using mechanical coolers, in addition to reducing the temperature of the meat, they also reduce these changes. It should be done within the first 24 hours.

This quick operation causes the meat to harden and the meat to drop and the muscles to shorten. In order to prevent this from happening, the steps must be carried out in two preliminary ways and then storage in the cold room halls.

The preliminary cooling is done for 18 to 24 hours. After the initial cooling, the carcass is transferred to the mortuary hall, where the temperature is about 2 degrees Celsius above zero. The carcass must be kept at a temperature between 1 and 2 degrees above zero for about 24 hours to a maximum of 72 hours. Before the carcass enters the cold store, they wash it with cold water and then dry the surface of the meat.

In the process of cooling the meat, the conditions should be observed in the best way, because the bacteria and fungi that cause the meat to spoil do not grow and do not lead to the phenomenon of bone rot. The bacteria that cause anaerobic bone rot are from the Clostridium category. They hang it in order for cooling air to easily pass between the carcasses.

After slaughtering the animal, if it is beef, it should be at least less than 20 degrees Celsius in the bone parts. If the freezing process is done slowly, it will damage the meat tissue and the quality will decrease.

According to the type of meat and its function, the cold storage is divided into two types of meat cold storage above zero and below zero meat cold storage.

Meat cold storage above zero

As the name suggests, the temperature range of the meat cold storage above zero is between 0 and 15 degrees Celsius. It is ideal if you want to store the products for a short period of time, such as a week. Cooling and reducing the temperature of the carcass should be done immediately after skinning. The slaughtering stage should be carried out for 10 hours after the slaughtering, the temperature of the depth of the carcass should reach less than +10 degrees Celsius.

The supply of proper humidity is between 85 and 95%, which reduces the weight of the meat, as well as the evaporation of the water in the meat, and the normal quality is maintained. It should be noted here that ozone gas is used in cold storage above zero to store fruits and vegetables because It causes ethylene gas not to spread and has the following positive results.

- Prevents the growth of fruit seeds

- Preventing re-ripening of fruit and early fruit ripening

- Prevention of fruit corrosion and spoilage

Meat cold storage below zero

As the name suggests, the temperature range is defined as below zero. This model of cold storage is used to store meat for several months. Therefore, they benefit from sub zero cold storage for freezing all kinds of meat and preserving it for a long time. The shelf life of the product is between 9 and 12 months, the meat can be kept frozen in the form of whole carcass, half carcass, quarter carcass, and cut, boneless. For this purpose, the meat can be stored in the freezing tunnel with a temperature of at least -35 degrees Celsius and froze with an air circulation speed of 3.5 meters per second.

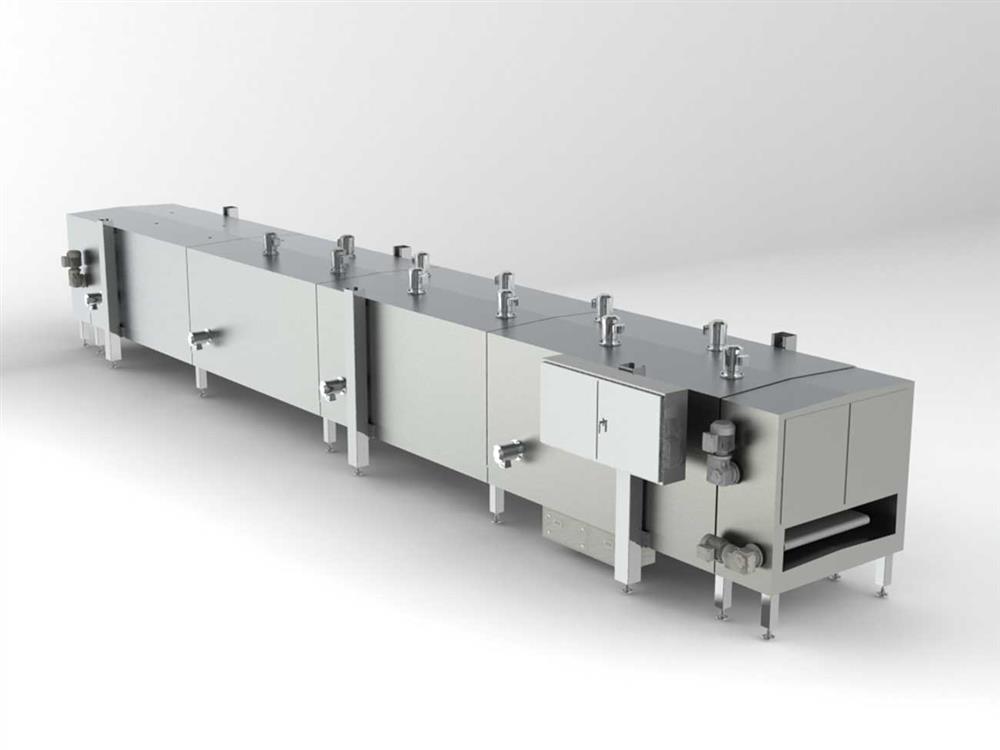

What is a freezing tunnel?

Freezing is done in different ways, fast freezing and slow freezing. If our goal is fast freezing, the freezing tunnel is a suitable option. The freezing tunnel is a powerful and large hall with a temperature limit between -30 and 60 degrees Celsius. These tunnels are used to freeze vegetables, meat, sea products and freeze with the same original quality without losing quality.

If we want to preserve food for a long time, the freezing tunnel is very suitable and it is offered in different uses, the chicken freezing tunnel, the vegetable freezing tunnel, the ice cream freezing tunnel, the meat freezing tunnel, the fish freezing tunnel and the fruit freezing tunnel are one of the most important The characteristics of the freezing tunnel are keeping the products for a long time and maintaining the original quality.

Disadvantages of very high humidity in meat cold storage

- Rapid growth of bacteria and greater possibility of meat spoilage

- Increasing water drops in the cold room, freezer and meat packing rooms

- Reduces the effect of cooling systems

- Preventing excess water from carcasses

- It provides the conditions for the growth and reproduction of fungus and mold on the surfaces of the facility.

- Providing an unhealthy environment for employees

- Destruction of equipment and corrosion of facilities and isolation system

Disadvantages of low humidity in meat cold storage

- Abnormal weight loss of meat during cooling

- It causes the color of the product to change and burns caused by the cold, resulting in an old and thin carcass

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Cold room sandwich panel, Types of sandwich panels

- Buying a cheap refrigerator in Iran, Buying a cold storage in Iran, Buying cheap meat cold storage in Iran, Buying cold meat in Iran, Buying cold storage of high-quality meat in Iran, Buying high-quality meat cold storage in Iran, Buying sandwich panel cold storage in Iran, meat cold storage, Meat cold storage in Iran, Sale of cold storage in Iran, Sale of high-quality cold meat in Iran, Sale of high-quality meat cold storage in Iran, Sale of meat cold storage in Iran, Sandwich panel refrigerator, Selling cheap meat cold storage in Iran, Types of cold storage in Iran