Our purpose of writing this article is to review and describe the disadvantages of low-quality panels. But in this regard, we will explain many things about sandwich panels, their related titles and even the benefits of a high-quality sandwich panel.

What is a sandwich panel?

Over the past few decades, sandwich panels have proven to be an excellent solution in the construction industry. By definition, this material is a self-sustaining component that serves two simultaneous purposes:

Partitioning (ceiling or wall)

- Insulation

Today, many buildings use cladding made of insulated sandwich panels.

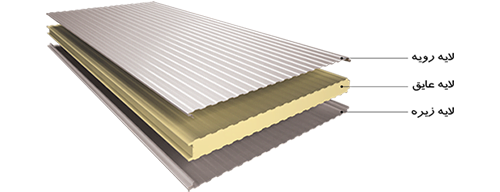

An insulated sandwich panel is a product consisting of an insulated core sandwiched between two metal or polymer composite shells. Cores can be made from a variety of insulating materials such as polyisocyanurate, expanded polystyrene, rigid polyurethane, and mineral wool. Of course, insulating cores may also be made of composite materials.

In fact, in the most basic terms to define a sandwich panel, it should be said that a sandwich panel is a type of panel that consists of three (or sometimes more) materials that are glued together to form a single unit. These panels are even called composite panels, because they are composed of more than one type of material. The reason for mentioning the sandwich in the naming of these panels is because of the configuration of the panels and the way they are built.

Sandwich panels are available in three main types. Each uses a specific panel core. Therefore, as mentioned, there are various types of panels with cores made of polyurethane, mineral wool, and EPS, each of which is intended to meet specific needs and be used in a specific location.

Sandwich panels have three basic components:

- Two layers facing out

- A thick core

By definition, it is such that the two outer panels are presented as the “bread” of the sandwich whose core is the meat.

Generally, these two facing layers are applied to help increase the overall durability of the panel, or in special cases additional layers can be added to the sandwich panel to increase other strength properties. For this purpose, in addition to the upper and inner parts of the sandwich panel, coatings that protect against mechanical damage and corrosion are also added to it.

Each of these layers and panel features can be very important to a project, depending on the environment in which the sandwich panel system is located.

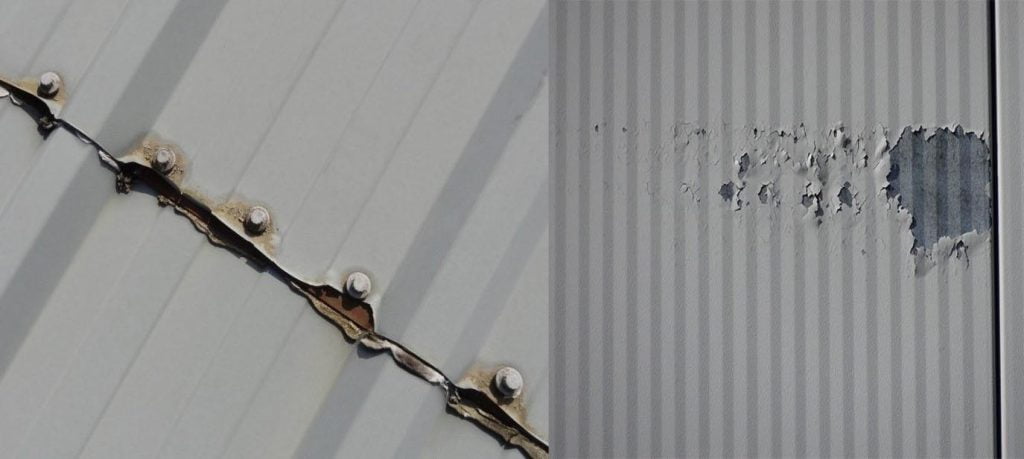

Poor quality sandwich panel

Walls and roofs of houses, doors and floor panels in the construction of vehicles and many other things are made of sandwich panels. So that individually designed sandwich panels have become an essential part of today’s life.

As mentioned earlier, the core and top layer materials help ensure mechanical strength. However, one process must be observed in this context, which is the ratio of the top layers to the core material.

In such a way that the core material must have such inherent strength and high compressive strength that the distance between the upper layers remains constant when the sandwich structure is bent. If this principle is not guaranteed, the bending strength of the sandwich panel will be lost immediately. Especially when these panels are used in the construction of vehicles. For this reason, the discussion of quality in this field is very important and one should be aware of its quality standards so as not to cause problems.

To know the quality level, you should check the product you want with the sandwich panel configuration. Depending on the application and place of use, required specifications and purpose of use, sandwich panel manufacturers can create the right product for you. The choice of different combinations of materials in the field of fiber-reinforced plastics is very large, and the available properties are as diverse as the choice of materials.

In general, if the insulation used in the panel is combustible, the risk of fire increases greatly. In fact, due to the impermeability of sandwich panels, it is often very difficult for firefighters to put out fires in buildings that have panels made of combustible products, which in most cases leads to the complete destruction of the building. In fact, the reason for this process is that combustible products are able to add large amounts of smoke and toxic gas to the fire.

These common insulation materials used in sandwich panels are rated according to their flammability level. We have previously mentioned the materials used and the types of sandwich panel flashing in detail, but in the following we want to describe the common and combustible materials:

Glass fiber or mineral wool is non-combustible.

It is true that fiberglass insulation is non-combustible, but it cannot resist fire like mineral wool. So that mineral wool can be used as a fire extinguisher. Of course, both materials are affordable and easy to install.

Polyurethane or polyisocyanurate is flammable.

The thermal insulation provided by polyurethane and polyisocyanurate foams can lead to rapid accumulation of heat in case of fire and may lead to its rapid expansion. Polyurethane and polyisocyanurate can ignite in the range of 343°C to 537°C and emit thick, black smoke as they burn.

Fiberglass-reinforced plastic (FRP) or glass-reinforced polyester resin is combustible.

FRP (reinforced polymer composite) material is a composite made of a polymer matrix that is reinforced with other materials such as glass and carbon. This material is often used in construction, in the aerospace industry. FRP also, like polyurethane and polyisocyanurate, ignites in the range of 343°C to 537°C and releases soot when burned, this material can melt and flow quickly and provide fuel for an existing fire.

Expanded polystyrene or polyethylene has a significant amount of flammability.

Since sandwich panels are not structural materials and are curtain materials that act as an insulating layer, they should be a factor in improving your quality and safety or comfort. Therefore, paying attention to quality is one of your priorities.

Quality has always been the most important issue in all cases that gives value to the product and its efficiency. Using a low-quality product is not only associated with wear and tear, but also wastes your money.

Types of sandwich panels

In general, sandwich panel types are grouped based on the thermal insulation material used as the core. Sandwich panels with EPS, mineral wool and polyurethane cores are all readily available. These materials mainly have differences in terms of thermal insulation performance, sound insulation, reaction to fire and weight.

Definitely, quality and difference are two completely separate and incomparable cases. Panel sandwiches also have differences from each other that are incomparable to the quality issue.

These panels differ in the following:

- the length

2 to 18 meters

- Thickness

40 to 230 mm

- Core type

Mineral wool, EPS, polyurethane

- Profile

Smooth, micro-profile, clear line, grooved, etc

- Protective covers

SP Polyester, SP Polyester Mat Pearl, Cesar PUR 55, Aluzinc

- Coating colors

Sandwich panels (both external and internal)

As you know, sandwich panels are available in two wall and ceiling versions, which are available for the following types of places and structures:

- Warehouses and logistics centers

- Workshop production facilities

- Cold stores and freezers

- Car exhibitions

- stores

- Recreational and sports facilities (swimming pools, fields and halls)

Advantages of using high-quality sandwich panels

Definitely, the high quality gives you the confidence and guarantee of comfort that cannot be expected from a low-quality sandwich panel. Below are some examples of the benefits of using sandwich panels.

Many people’s attention has been directed to the aesthetics and facade styles along with the basic function of industrial structures. A good and beautiful appearance of a business place, whether it is a manufacturing plant or a store or even a car showroom, most of the time shows the level of trust in the present brand. Sandwich panel offers many interesting solutions with a wide range of coating types and coating colors, which is the reason for their beauty and effectiveness.

Even a wide range of these selected designs can be connected arbitrarily or based on aesthetic principles, which can have wonderful results to attract attention and make the business stand out, no matter if the style is more classic or be more modern Due to the fact that the surface of these panels is smooth and non-porous, they can be cleaned quickly and easily. Since the covering materials of these panels are completely resistant to factors such as physical impact and liquids, regular cleaning will keep the structure and appearance clean and new for several years.

Aesthetic judgments influence our feelings and preferences. Aesthetics is narrowly defined as the study of beauty. This point is definitely not irrelevant in relation to your work environment and its effect on your performance. Using beautiful structures will definitely bring good results and surprise you. The effect of sandwich panels on the beauty of decoration is an undeniable issue that will improve the appearance of your workplace.

Comparing the two common technologies used in construction, between the use of building materials and sandwich panels, sandwich panels will definitely be the best option. Consider that in one case the external partitions consist of double brick walls, while in the other case they consist of sandwich panels.

Regarding the first case, it is necessary to get help from the following tasks:

- Wall construction

- Installation of thermal insulation

- Installing the outer layer

These things do not apply to the sandwich panel, and its application is much easier and more economical (both in terms of time and cost). Panels are final components that are suitable for easy installation, for example for a steel structure, considering the current situation in the construction services market, working time plays a key role in the cost optimization process. The quick completion of the structure process results in lower construction service costs. Since these kinds of costs have increased significantly in recent years, quick completion of structures can be considered as an improvement factor in the percentage of costs created.

In general, since quality sandwich panels require very little maintenance and can withstand all types of weather, they are very durable and have a long lifespan. They are ideal for structures that are built to last. At the same time, compared to building materials, they are not so expensive and expensive;

Therefore, it is an excellent choice for all kinds of construction projects. These panels have recently been widely used in construction due to their numerous advantages. Aesthetic appeal as well as design potential make them an ideal choice for architects. In addition, their acoustic properties give them an advantage over other roofing materials in construction. A quality, impermeable coating can act as a moisture barrier for a wall or ceiling panel in a home. A wear-resistant coating can be applied to the top surface of a floor panel.

The quality of any product depends on your choice and the materials used to make the product. Sandwich panel is a protective sample that is installed to cover the roof and prevent the entry of any pollutants and moisture. Therefore, a low-quality panel will not lead you to the desired goal and will have a poor performance in covering the roof or walls. Therefore, use the information provided for the advantages and disadvantages of sandwich panels and make the best possible choice. To view the videos, you can refer to the video gallery.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Cold room sandwich panel, Office conex, Polystyrene sandwich panel, Polyurethane sandwich panel, Roof sandwich panel, sandwich panel xps, Types of sandwich panels, Wall sandwich panel

- Buy ceiling sandwich panels in Shiraz, Buy sandwich panels in Shiraz, Buy sandwich wall panels in Shiraz, Cold room sandwich panel in Shiraz, Installation of ceiling sandwich panels in Shiraz, Installation of sandwich panels in Shiraz, Installation of wall sandwich panels in Shiraz, Poor quality sandwich panel, Roof sandwich panel, Roof sandwich panel in Shiraz, Sandwich panel, Sandwich panel in Shiraz, Sandwich panel installer in Shiraz, Sandwich wall panel in Iran, Sandwich wall panel in Shiraz, Selling ceiling sandwich panels in Shiraz, Selling sandwich panels in Shiraz, Selling wall sandwich panels in Shiraz, The price of ceiling sandwich panel in Shiraz, The price of sandwich panels in Shiraz, The price of wall sandwich panels in Shiraz, Types of sandwich panels in Iran, Wall sandwich panel, Wall sandwich panel installer in Shiraz