How much does it cost to build a cold room with sandwich panels?

A cold room is a closed environment that is used with a specific and standard temperature to freeze and store food and other materials that can spoil at the temperature outside the cold room.

In the past, the construction of cold storage was done using traditional building materials, which entailed high time and costs. Materials such as sand and gravel, concrete and cement, thermal insulation of glass wool and cotton wood, waterproofing of bitumen and sacking, etc.

But today, new and practical building materials have replaced expensive and old building materials, and by using this type of building structure, the construction of cold storage has become very easy and affordable.

Sandwich panel is one of the newest building materials, which is widely used in the construction industry, especially in the construction of cold storage, due to its extraordinary advantages.

To build a cold room, all the walls, ceiling and floor must be made of strong and washable insulation. This important thing prevents the loss of energy, increases the lifespan of the cold storage, and prevents corruption and deterioration of the materials inside it.

In fact, a standard and high-quality cold room should be able to preserve the freshness and freshness of the products and food inside it in the best way at low temperature.

Cold stores are usually used in the food industry, pharmaceutical industry, flower and plant production, large industrial factories, laboratory and medical equipment, etc.

The constituent parts of the mortuary

Guard room

Upon entering the mortuary environment, we encounter this room, which is intended for the security of the mortuary.

the preparation

It is a place that has a higher temperature than the temperature of the cold room and is used to reduce the initial temperature of food.

Some products, before directly entering the chambers, are kept for some time in the preparation room so that their temperature decreases slowly, and then they enter the main hall. This prevents sweating, mold and food spoilage.

Freezing tunnel

It is a part of the cold room that has an extremely low temperature of about -40 degrees and is used to quickly freeze some food items. Fast freezing of the ingredients preserves the quality of the product and its primary characteristics such as color, smell, taste, texture, etc.

Mortuary platform

It is a roofed shed with a height of 1 to 1.2 meters from the ground level, which is located at the beginning of the entrance of the cold room and is used to transfer goods inside the cold room.

Mortuary halls

These large halls include ten chambers equipped with temperature control and humidity control systems, each of which has the capacity to cool 500 tons of products and has a specific temperature according to the materials stored in them.

The temperature control system is carried out by nitrogen with a temperature of -196 degrees Celsius, and it keeps the temperature of the chambers at a fixed and specific value.

The humidity control system automatically measures the temperature inside the cold room. If there is no required humidity inside the cold storage, the quality of some materials such as fruits will decrease and cause wrinkles on the fruit. Therefore, it is very important to regulate and control the humidity level of the cold room.

Cold storages are divided into several categories based on temperature, and each of these two types requires special construction and designs.

Cold room with temperature above zero

Cold rooms with temperatures above zero degrees are used to store fruits, vegetables, dairy products and other items that should not be frozen, such as medicine.

Cold room with below zero temperature

Cold rooms below zero degrees are used to freeze chicken, meat, fish, shrimp, etc. It should be noted that cold storages with temperatures below zero can be used by adjusting the temperature to store materials that require temperatures above zero, but cold storages above zero cannot be adjusted in such a way that it has the ability to preserve products that need to be frozen be.

It is practically very difficult to do this and it causes a lot of pressure on the engine of the refrigerator.

Freezing tunnel

These types of refrigerators have a very low temperature of -40 degrees and are used to quickly cool and freeze food.

Dual purpose cold storage

Some cold stores provide both sub-zero and above-zero temperatures to store materials and goods inside the cold store.

Types of cold storages based on their use

- Storage cold room as a warehouse for food storage

- Customs cold storage for short-term and temporary storage of goods and food

- Public cold storage to preserve products and food

- Small refrigerator for storing ice

Technical components of cold storage

In fact, it can be said that cold storages are very large refrigerators that are used to store many types of perishable food. Therefore, they have common technical parts. Below are some of these pieces.

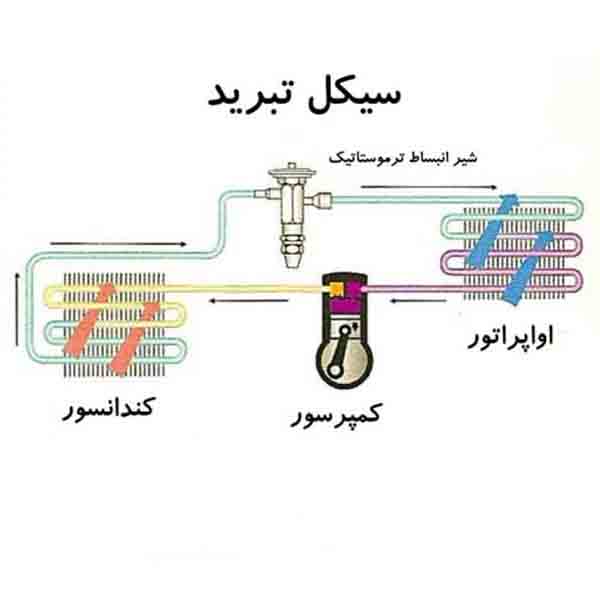

Compressor

It is the engine of the cold room, which is considered the main and essential part of the cold room. The operation of cold room and refrigerator compressors is the same and the only difference between them is the difference in the type of compressors.

condenser

By converting the refrigerant gas into liquid, the condenser is responsible for cooling the gas from the refrigerator compressor.

operator

It is a part that has the opposite function of the condenser and in it, the refrigerant liquid turns into gas and makes the temperature of the surrounding environment cool.

Thermostat

It is a tool that measures and controls the temperature of the cold room in coordination with other equipment.

What is a cold storage sandwich panel?

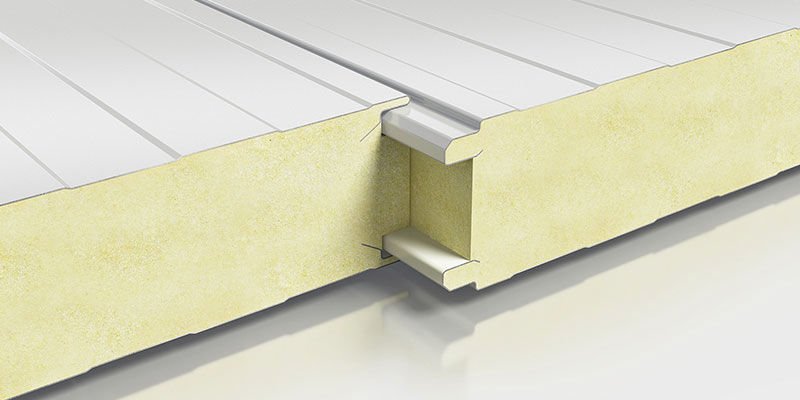

Cold storage sandwich panel is a three-layer structure made of a hard and fragile material called flame retardant polyurethane with a density of 40+2 kg/m3, which consists of two strong outer layers of metal on the sides and a light inner layer in the middle.

Three types of galvanized, aluzinc and aluminum sheets are used to cover the layers of cold storage sandwich panels according to the customer’s needs and requests.

This new and ready-made building material is used as thermal insulation in the construction of fixed and mobile cold storages, and it is considered a resistant insulation against the entry of heat and the exit of cold, humidity, sound, air pollution and the entry of insects.

Due to its ease of installation, high strength and light weight, sandwich panel is considered a very suitable alternative to old building materials.

The design of the sandwich panel of the cold room is such that it has deep and raised grooves that completely overlap when installed and placed together.

Sandwich panels are produced and marketed in two types, wall and ceiling, and are used to cover walls, ceilings, and floors.

This prefabricated material is in the form of parts separated from each other, which are easily placed next to each other by installation experts and ordered in different sizes and sizes, according to the customer’s taste.

Types of cold storage sandwich panels

Cold room wall sandwich panel

This type of sandwich panel is available in thicknesses of 8 to 15 cm, easy and clean installation, high resistance, light weight and non-flammable, and economical.

All these positive features have made this product a suitable choice for covering the walls of the cold room.

The thickness of the wall panels is determined according to the desired amount of cold in the cold room. For example, in cold stores with temperatures above zero degrees, we need thinner sandwich panels, and in cold stores with temperatures below zero degrees, we need thicker panels due to high energy consumption.

Cold room ceiling sandwich panel

The insulated ceiling sandwich panel is considered to be resistant and at the same time light, which with its special structure and efficiency, prevents the transfer of heat and humidity from the roof into the cold room, thus preventing the wastage of energy.

These sandwich panels are produced in dimensions of 4 to 10 cm and are designed in such a way that by completely covering each other’s grooves, it prevents water and humidity from entering the cold room.

Types of cold storage sandwich panels based on the material of the outer layer

- Sandwich panel, one side of foil, one side of sheet

- Sandwich panel, one side of sheet, one side of paper

- Double-sided foil sandwich panel

- Double sided nylon sandwich panel

It should be noted that sandwich panels with double-sided nylon are used to cover the floor of the cold store, and at the end of the coating work, the surface of the panel is poured with concrete. This work reduces the amount of heat transfer and the ambient temperature.

Double-sided nylon sandwich panels, compared to other sandwich panels, are naturally lighter due to their lower weight, and using them for the construction of cold storage significantly reduces the cost of consumption.

Advantages of cold storage sandwich panels

- Heat insulation

- Impact resistant

- Light and light weight

- moisture insulation

- to be economical

- Quick and easy installation

- Resistant to decay and corrosion

- Energy efficiency

- Beautiful and clean appearance

- Sound insulation

- Various designs and colors

- Easy to move

- Washable

- Can be used in all situations

- Resistant to natural disasters such as wind, flood, etc.

- High flexibility

The price of cold storage sandwich panels is different and this difference is caused by the following factors:

- Material and thickness of sandwich panel cover sheet

- Insulation level

- Variety of designs and colors

- The density and thickness of the foam used in the sandwich panel

- Weight and strength

- Being fireproof

- High pressure tolerance

The cost of building a cold room with sandwich panels

The cost of building a cold room depends on factors such as the dimensions of the cold room (the most important and fundamental factor determining the cost of building a cold room), the quality of sandwich panels, the type, use and price of each building material, the temperature of the cold room (above zero degrees or below zero degrees), installation quality, brand It depends on construction equipment, single-phase or three-phase electricity (the cost of building a house using single-phase electricity is higher) and so on.

In general, before building a cold storage room, one should carefully evaluate the side and related costs with full knowledge and consult with experts in this field, and then start building the cold storage room.

last word

The use of insulation in cooling systems, including cold storage, is extremely important. In fact, the main task of the refrigerator is to quickly freeze and protect the food inside it by maintaining the temperature of the refrigerator. For this purpose, choosing strong insulation prevents the entry and exit of heat and cold by optimizing fuel consumption and keeps the contents of the cold room healthy.

Cold storage sandwich panel is one of the best and most suitable insulations and coatings used in the construction of cold storage, which today has replaced traditional building materials such as cement and brick, and is widely used in the construction of cold storage walls, floors, and ceilings.You can visit the YouTube channel below.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square

- Cold room sandwich panel, Types of sandwich panels

- Buying a cold room with sandwich panels in Shiraz, Buying a cold store in Shiraz, cold room, Cold storage above zero in Shiraz, Construction of a cold room with sandwich panels in Shiraz, Construction of cold storage in Iran, Fixed morgue in Shiraz, Installation of sandwich panel cold storage in Shiraz, Installer of cold storage with sandwich panels in Shiraz, Kimia Panel factory in Shiraz, Mobile morgue in Shiraz, Multipurpose cold storage in Shiraz, Sandwich panel cold storage in Shiraz, Selling cold storage with sandwich panels in Shiraz, Single-purpose cold storage in Shiraz, Subzero cold room in Shiraz, The cost of building a cold room with sandwich panels, The price of cold storage with sandwich panels in Shiraz, Types of sandwich panels, Types of sandwich panels in Iran, خرید سردخانه در شیراز