Do you know what a ceiling sandwich panel is?

Are you familiar with its specifications and applications?

Do you know the benefits of using it?

Stay with us until the end of the article, we will provide you with complete and comprehensive information to answer the above questions.

Today, there are many solutions to prevent energy wastage. One of the solutions that can prevent energy wastage to a great extent and is considered as an excellent protector is called sandwich panel.

There are different types of sandwich panels, each of which is used in certain situations. Here we are going to introduce one of the most widely used ceiling sandwich panels and provide you with a complete explanation regarding its specifications, uses, features, and advantages.

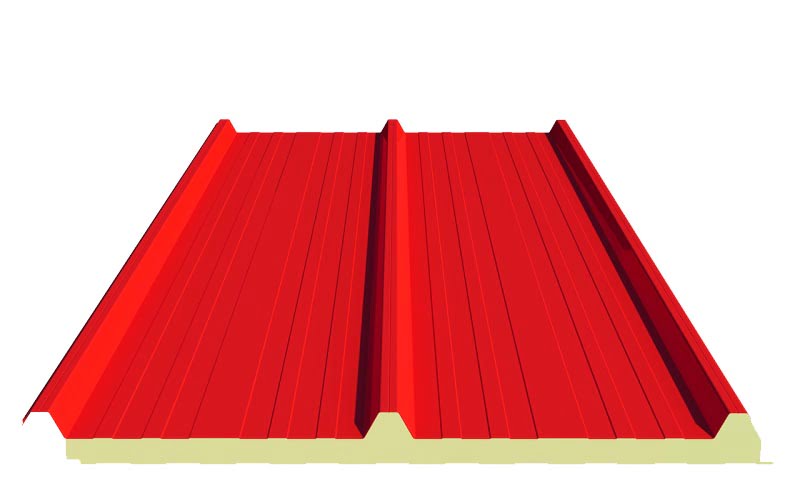

Introduction of ceiling sandwich panel

According to the name of this panel, you will understand that it is used to cover ceilings; Of course, it has many other uses that we will mention below.

This type of sandwich panel is made of different materials that are used depending on different situations; But in general, they have very high resistance. The roof sandwich panel cover is such that if their surface is scratched, they will not suffer from corrosion or rust.

Also, regarding the foams that are used in their construction, we must say that these foams actually play the role of insulation and these insulations can be of different materials such as polyurethane, polystyrene, rock wool, xps insulation and glass wool. In the next section, we will talk about the most widely used insulations used in this structure.

In general, you should know that the ceiling sandwich panel consists of three layers:

- Top layer

- Sole layer

- foam

Foam refers to the insulation that we talked about before, and today polyurethane foam is used more between the other two layers; Because the adhesion of this foam is extremely high and makes these three layers never separate from each other. In other words, the existence of these three inseparable components makes this structure act as an integrated object as a very powerful protection.

Inspection of ceiling sandwich panels in terms of insulation

As we explained in the previous section, these structures are made of different insulations. In this part of the article, we are going to talk about these insulators.

The types of insulation used in ceiling sandwich panels are:

- Polystyrene insulation: This insulation is white in color and is made of solid polystyrene beads. This insulation has very little weight; But it does not have much resistance to heat and fire compared to other insulations.

- Polyurethane insulation: this type of insulation is used to cover the ceiling sandwich panel. It is interesting to know that this insulation is composed of three other insulations, which finally creates polyurethane insulation.

- xps insulation: xps insulation is the same as polystyrene insulation. The only difference between them is that xps insulation has less resistance and thickness.

- Rock wool and glass wool: Glass wool and rock wool have had various uses since ancient times, but with the passage of time and the advancement of technology, they are no longer used much; But in general, we must say that glass wool has a very high resistance to fire and heat and can be a very good insulator.

This feature has made glass wool able to prevent energy wastage to a great extent; But over time, due to high humidity, they are corroded and you should know that this corrosion is very dangerous and is not recommended for use in places such as cattle farms, poultry farms, food warehouses, etc.

Physical characteristics of ceiling sandwich panels

In this part of the article, we will examine the physical characteristics of the ceiling sandwich panel and examine the important items in full detail.

Physical characteristics:

- Length: 2 to 14 meters

- Width: fixed 1.08 meters, useful 1.01 meters (overlap 7 cm)

- Thickness: 4, 5, 6 and 10 cm

- Sheet design: hidden screw, shadowline, plain, clay or trapezoidal

- Sheet type: aluminum, galvanized, PVC, stainless steel, copper and aluminum

The things we mentioned above are the physical characteristics of the roof sandwich panel, which depending on the customer’s consumption and of course the order she gives, one of the types of sheets in the desired dimensions is used for construction.

Applications of ceiling sandwich panels

There are many applications of sandwich panel ceiling and we are trying to talk about its applications in this part of the article.

As you know, in the past, in order to protect and prevent energy wastage, they used other structures that were not practical in every place; But today, the needs of every customer are met with these new structures, and depending on the customer’s needs, the ceiling sandwich panel can be ordered in the desired dimensions and design.

The general applications of this structure are:

- Can be used to build the roof of structures, sheds and buildings

Can be used in structures such as non-industrial and industrial silos, warehouses, etc.

- Can be used to build condos

Can be used in large sheds such as large sports halls, cattle farms, chicken farms, etc.

- Can be used in airplane hangars and villa buildings

- Can be used in transport container walls

- Can be used in covering the roof of mobile and fixed cold storages

Features of ceiling sandwich panel

The features of the ceiling sandwich panel are:

- This type of sandwich panel can be used in all climatic conditions and it is necessary to know that formatting is not required in this case; Therefore, in any weather condition, this type of structure can be implemented as a protective structure.

- These types of structures have very low expansion and contraction properties and have a very high resistance to moisture.

- Roof panel sandwiches are designed and made in such a way that they are highly resistant to pollution.

- These types of structures have a very high resistance against earthquakes and landslides.

- These structures have very high safety and do not suffer much damage from accidents.

- One of their very important features is the compatibility of these structures with the environment. You should know that these structures do not produce smoke and therefore do not harm the environment.

- In addition to the above, we must say that these structures show great resistance against chemicals.

- If alozinic sheets are used in these structures, the roof sandwich panel becomes resistant to ultraviolet rays.

- Their high resistance against rusting is also one of their important features, and of course, it goes without saying that the presence of aluzinic sheets creates this feature in the structure.

Advantages of using ceiling sandwich panels

This category of structures has great advantages and you should know that their advantages are so many that it is known as one of the best-selling structures in the market today.

The most important advantages of using this structure are:

- These structures are fireproof. They show a lot of resistance against fire.

- These structures are designed in such a way that its components must be connected to each other using bolts and nuts, and for this reason, they can be easily assembled and disassembled.

- In general, they have very good strength and resistance, and for this reason, it can be said that their lifespan is longer than other structures.

- Ceiling panel sandwiches can be ordered in various colors depending on the customer’s taste in the workshops.

As we said, the lifespan of these structures is long and due to their good features, they are sold at a very affordable price in the market.

- The materials of these structures are chosen in such a way that they do not attract dust and dirt.

- It is also necessary to know that these structures are washable and this is one of their best advantages.

- In general, roof panel sandwiches are light in weight; But you should know that their low weight does not affect their quality and the structures are designed and built in a super professional manner.

- As we mentioned before, they are connected to each other using bolts and nuts, and this has made it possible to move this structure easily.

Why do they use roof panel sandwiches instead of using traditional materials today?

In the previous sections, we talked about the specifications, uses and advantages of these structures and stated that these structures have extraordinary features. In this part of the article, we intend to explain the reason for replacing these structures instead of traditional materials.

- This type of structures can be used not only in modern industries, but also for the reconstruction of old buildings and structures.

- The next thing that caused the replacement of these structures instead of traditional materials is their structure, which we explained in the above sections.

- The roof sandwich panel is made of a low-density core, and a variety of hard and rigid metal sheets form the outer layers of this structure.

In addition to the strong structure of this structure, we can mention the multi-purpose and beauty of these structures, which is a very important factor in replacing these structures instead of traditional materials.

How to install a ceiling sandwich panel

In this part of the article, we will talk about the important points in installing these structures. As we mentioned in the previous sections, these structures are implemented at height (ceilings) and are sometimes exposed to rain, snow, etc. For this reason, it is necessary to install them correctly; Therefore, the installation of these structures should be undertaken by people who have sufficient expertise and skill in doing this work.

In the installation of roof panel sandwiches, galvanized screws with washers are used. These screws play the role of connecting the roof to the frame. Next, they use plastic washers to tighten the screws, and the reason is that these washers can prevent the penetration of snow and rain, etc.

In general, when installing this structure, it is necessary to consider the following:

- It is necessary to use screws with washers and the height of the screw and the structure must be proportional to each other.

- Be careful to use one galvanized screw per square meter of ceiling panel.

- They use Abro and flushing sheets for sealing and beautifying the appearance of the structure.

- It is necessary to carefully pay attention to the empty space between the panels and overlap the panels well on each other.

You can also visit our YouTube channel.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square