Aluminum sandwich panel (kimia panel) in Shiraz

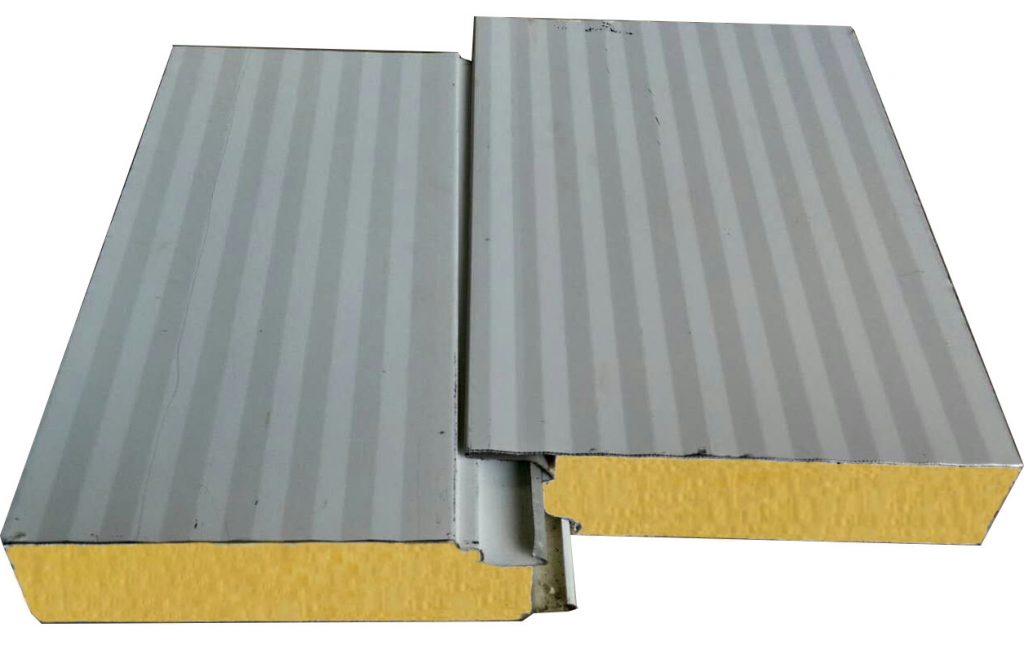

Aluminum sandwich panel is a panel that consists of three coherent layers. These three layers include two layers of sheets that are limited on the sides and a layer of foam that covers the middle part. The side sheets are made of aluminum metal and the middle part is made of polyurethane foam. These sheets are covered with polyester paint and primer.

Today, with the increase in population, the need of people to build stable and affordable structures has increased. Therefore, prefabricated materials such as sandwich panels have become popular. Sandwich panel has a composite structure consisting of three layers and shows unique features due to the special material used in it. This combination has made the prefabricated material usable in hot and cold regions.

In this article, we are going to examine the details of the aluminum sandwich panel. Join us for more information in this field.

Table of Contents

What is aluminum sandwich panel?

The sandwich panel is a new and prefabricated product that consists of three main and coherent parts. The sides of the sandwich panel are covered with aluminum metal and the middle core is injected with polyurethane foam. The type of body cover makes the panel have special features and different applications. The upper and lower sheets of the sandwich panel are covered with a layer of polyester paint and a special primer.

Sandwich panel with its middle core is widely used in industrial and commercial buildings. Polyurethane foam is generally used in the core of aluminum sandwich panel. This type of sandwich panel is used in both wall and ceiling types in industries such as automobile manufacturing, shipbuilding, and building construction. At the beginning of the article, we mentioned that the aluminum sandwich panel is a type of sandwich panel in which the top and bottom sheets are made of aluminum metal and the middle core is covered with polyurethane insulation. This type of panel is light because of the thickness of the aluminum sheet. It is about less than 0.2 mm.

One of the most important features of aluminum panel is light weight, reasonable price, flexibility, high malleability, attractive and beautiful appearance, and colorability.

What is aluminum sheet?

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Aluminum is a very light and flexible metal that can easily be bent. This metal is very resistant to corrosion and decay and is the best conductor of heat and electricity. Aluminum sheets are produced in the form of thin sheets. Due to its special characteristics, this metal is widely used in the construction industry and is of great importance.

Advantages of aluminum sandwich panels

The use of aluminum sandwich panels is associated with various advantages. The features of this sample of prefabricated panels make it a better choice compared to other sandwich panels. Some of the most important advantages of aluminum sandwich panels are as follows;

- Light weight and optimal price: Aluminum is a light metal that is used in the construction of sandwich panels, due to its light weight, it is easy to transport and is affordable. The structures produced with the help of aluminum sandwich panels are light in weight and They have a long shelf life.

- High thermal coefficient of aluminum sheet: Aluminum is a conductive and conductive metal (any material that passes electricity well is called a conductor or conductor). For this reason, this product can be used to make heat exchangers and kitchen utensils.

- Non-toxicity: Aluminum alloy reacts easily when it is in the vicinity of air and creates a layer of aluminum oxide. Therefore, aluminum panel is considered a non-toxic product and is used in the health, pharmaceutical, and food packaging industries. has many

- Ability to reflect light: Aluminum sheet reflects light completely. This property is very practical and can be used in making light reflectors, making protective plates against light, infrared thermal radiation and radio waves. Therefore, this metal is suitable for receivers, radio transmitters and solar batteries.

- Corrosion resistance: Due to the contact of oxygen with the top layer of aluminum and the production of other oxides on the surface of the alloy, if it is placed in the vicinity of elements and chemicals, it does not react. The presence of aluminum oxide on the surface acts as a protective layer and prevents the decay and corrosion of the underlying layers.

- Color variation: aluminum sandwich panel can be produced with different color variations. This product can be dyed in 40 different colors. In addition, 40 colors depending on the customer’s order can be produced with any desired color. The most important feature of aluminum is the colorability of this product, and it causes the production of aluminum sandwich panels with high color diversity.

- Flexibility: The aluminum metal used in making sandwich panels has favorable properties, which include malleability, flexibility and malleability.

- Stability and resistance: approximately 85% of the aluminum alloy used in the construction of panels can be recycled and produced. Choosing aluminum in construction is considered the best option from an environmental point of view, so the panel is one of the sustainable building materials.

- Anti-fire and fire: covering the middle core of the aluminum sandwich panel with polyurethane foam is a good insulation against fire. Heat and fire resistance in aluminum panels is due to special materials in the middle layer. Therefore, these panels are used in the construction of large buildings. Like towers, skyscrapers and tall buildings that are more than 40 stories are used.

Disadvantages of aluminum sandwich panels

- Aluminum sandwich panel cannot be washed. Therefore, it cannot be used in places where disinfection and hygiene are a priority.

- This product has a high conductivity coefficient. Therefore, it performs very poorly in saving thermal and cooling energy and is not considered a good insulator.

- Aluminum sandwich panel is limited in terms of the number of designs, and the reason for this is due to the softness of aluminum alloy. It has less resistance and durability than other metals.

- The very high flexibility that this alloy has is considered a negative point because it has a short lifespan compared to other panels.

- Due to its high thermal coefficient, aluminum sheet easily changes its shape and loses its structure against fire.

- Aluminum alloy is weak against the penetration of water moisture, and if it is placed in the vicinity of water, the aluminum coating will split.

All kinds of aluminum sandwich panels

Aluminum sandwich panels are generally produced in two types, ceiling and wall. This model of sandwich panels is produced with a middle core of polyurethane and polystyrene. Sandwich wall panels with aluminum sheets have similar specifications. Light weight, cheap price makes it easy and has been noticed by installers.

Application of aluminum sandwich panel

Aluminum sandwich panel is produced in two types, wall and ceiling. This material has many uses, which include:

- Packaging and transportation industries

- Shipbuilding industry

- automobile manufacturing

- Construction of outdoor balconies

- Floor and ceiling covering

- Covering the walls of the structure

- All kinds of sheds, all kinds of cold storage and sheds and military structures

- Construction of a clean room or clean room (refers to a place where air can enter and exit and dust does not enter inside and must be brought in with a special bag).

- Finally, it can be said that double-smooth aluminum sandwich panels are used in the construction of rooms for laboratory and hospital use.

Technical specifications of aluminum sandwich panels

As we mentioned, the aluminum sandwich panel is designed and produced in two types, wall and ceiling. The aluminum sheets used in the aluminum panel are produced with a thickness of 0.4 to 0.7 mm, and the thickness considered in the wall panels is between 3 cm and 15 cm. Also, in the ceiling sandwich panels, the thickness is about 4, 6, and 8 cm and Finally, it is 10 cm.

Aluminum sandwich panel price

One of the most important factors regarding the sandwich panel is the price of the sandwich panel. The price of the aluminum sandwich panel depends on several factors such as the type of foam, aluminum sheet, the dimensions of the sandwich panel and the type of panel.

Business owners order according to their needs, type of use, desired dimensions. Therefore, from the beginning of using the sandwich panel, the user should be considered. In this way, the place where it will be used is important, and according to the above and the price of the day, contact the numbers listed at the bottom of the article. kimia panel with many years of useful experience. The provider of all kinds of ceiling and wall sandwich panels is ready to serve you with the best raw materials and the use of efficient staff.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square