The price of sandwich panels in Isfahan city

Isfahan sandwich panel is a new prefabricated product, consisting of three layers of top and bottom layers made of galvanized sheet, aluminum, aluzinc, thin but strong, and the middle core is made of thick and very light materials. The middle core can be made with polyurethane materials, Polystyrene, xps and stone wool covered. This insulation is very soft and flexible and has lightened the weight of the structure.

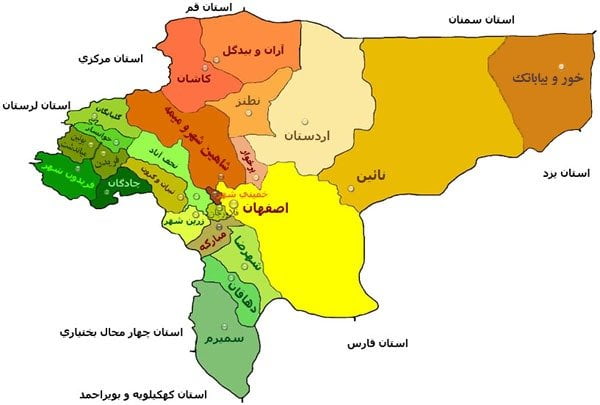

Isfahan province, with the center of Isfahan city, is the sixth largest province and the third most populous province of Iran. Isfahan province has the most neighboring provinces around its suburbs. It is limited from the east to Yazd and South Khorasan provinces, from the north to Semnan, Qom and Central provinces, from the west to Lorestan province and Chahar Mahal Bakhtiari, and from the south of the country to Kohgiluyeh, Boyer Ahmad and Fars. it counts.

This province has large industries; Such as iron smelting, Mobarake steel complex, refinery, numerous ceramic and tile factories, stone quarries and stone cutting that can be mentioned. Despite the high industrial production, Isfahan province has many industrial towns, it is probable that the use of sheds in this province is large. The construction of the shed is done with sandwich panel prefabricated material, which is very low cost and durable and affordable.

Sandwich panel is generally divided into two separate categories.

Isfahan roof sandwich panel

Isfahan wall sandwich panel

Sandwich panels are very diverse in terms of covering and covering the upper and lower layers, which include

Double sheet, single sheet of Ecrofoil, single sheet of paper, single sheet of nylon, double nylon, double foil

Advantages of Isfahan sandwich panel

- Resistant to corrosion and rot and rust caused by moisture

- Resistant to any weather conditions

- Resistant to thermal energy, refrigeration, sound

- Resistance to chemical agents and acids

- Anti-fungal, mold and insect infestation

- Completely hygienic and can be disinfected and washed

- Eco-friendly

- Very long life

- Light weight structure and ease of transportation

- Resistant to cuts caused by earthquakes

The sheets used in making sandwich panels in the top and bottom layers are aluminum, aluzinc and galvanized. Currently, the best type of sheet for making panels is aluzinc sheet, but unfortunately it is not produced in our country.

Sandwich panels produced with galvanized sheet are of high quality, but if the type of sheet used is not strong enough, it will cause rust and rot, and as a result, it is required to be replaced.

The central core used between the two layers of the sheet is insulating foam, which is one of the components of the sandwich panel and has a great impact on the quality of the product. This central core can be produced in several types, including polyurethane, polystyrene, stone wool xps materials, and each has special characteristics.

The best type of insulation is polyurethane material, which has special strength and resistance compared to other products. Before buying a sandwich panel, you should pay a lot of attention to the brand of the panel. Currently, many Jat factories are producing this product in the country, and one of the most important of them is the Kimia Panel factory.

You can communicate with sales experts to provide advice and guidance and prepare your desired structure. One of the factors that are prioritized when ordering is the thickness of the product, which affects the strength and resistance of the structure. Preferably, the thickness of the panel should be asked from the sales experts before buying. Then proceed to purchase. Another important factor for buying a panel is choosing the type of sheet. As mentioned, it is currently the best type of galvanized sheet. Therefore, the type of panel covering is very important. If it does not have a proper cover, it will be destroyed.

One of the important factors in determining the strength of the structure is the type of glue used to connect the foam to the sheet. Special care should be taken so that the sheet does not separate from the foam and does not get damaged. The density of the middle core is another important factor for ordering sandwich panels. The density plays an important role in the strength of the structure and can change the weight of the structure. Therefore, the density of the foam must be determined before ordering, and it is one of the factors that must be considered before purchasing. For advice, you can refer to our contact page and contact sales experts.

The price of ceiling and wall sandwich panels is constantly changing due to market fluctuations. Therefore, a specific price cannot be determined. It is better to communicate with the company’s advisors before ordering. The price of sandwich panel is determined per square meter. The price of the panel is affected by the thickness of the sheet, the type of insulation, the density and the type of the sheet. We are glad that you helped us until the end of the article. Hope the content is useful.

Sending the order of a dear customer to Isfahan province

Isfahan sandwich panel price

In terms of the central core, the sandwich panel has several types of core, which have different properties, the level, manner and quality of connecting the core to the surface and the quality of the production process. In the rest of the article, we are going to introduce you to the types of sandwich panels and the tips for buying panels. Due to market fluctuations, the sheet price is changing daily. Therefore, to know the price, you can contact the company’s experts and consultants.

Roof sandwich panel, as its name suggests, is used to cover the roof of structures. Sandwich panel ceiling has a lot of variety. Before ordering the structure, you should get information about its strength. You should pay attention to the number of steps and the type of step of the ceiling sandwich panel. The smaller the number of steps, the higher the weight bearing capacity of the structure will be. The ceiling panel is used to cover the roof of sheds, airplane hangars, and the roof of prefabricated structures.

Wall sandwich panels are used to cover the walls of structures and are very diverse. Before buying this product, you should pay attention to the type of sheet and the type of insulation used and the thickness of the product, then place an order. When ordering the desired product, you should consider the size, type of connections, all necessary conditions and specifications, and the size of the product.

What is the use of Isfahan sandwich panel?

- Covering the walls of the structure and roofing the sheds and containers

- Construction of field military centers

- Construction of prefabricated houses and villas

- Mobile clinics and relief centers

- Public and private places

False ceiling of indoor pools - and clean room

- Construction of schools and cultural places

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square