What are the methods of sandwich panel production?

Sandwich panels are modern materials that have attracted the attention of engineers and architects today, and their use has become very popular. These modern structures are more prosperous in the construction industry due to their many features. ¬, in this article, we intend to provide you with information about the methods of sandwich panel production.

In general, there are two methods for the implementation and production of these panels, both methods are used to produce modern prefabricated materials. Each of these methods has its own characteristics, which will be explained in detail below. .

1) Continues method

2) Discontinues method (discrete)

Discontinuous (discontinuous):

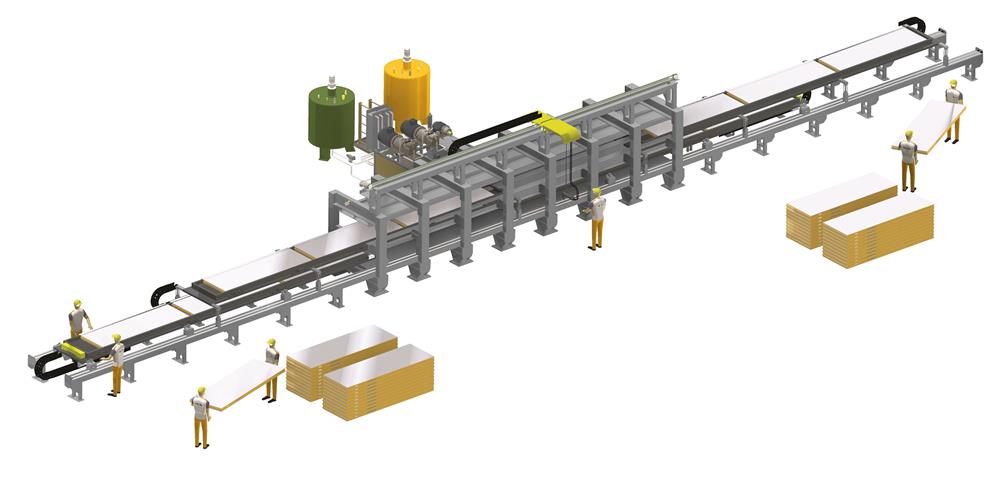

One of the most widely used methods for producing ceiling and wall sandwich panels is the opposite of the previous method because it is done discretely and separately.

The production line of this method is completely separate and each part performs its own operation and enters the next phase of production, in this phase it is produced in two ways:

- Discontinuous with polyurethane foam: in this method, each part is produced by a separate machine. First, the sheets are cut to the desired size and the customer’s needs, then the upper and lower sheets are formed, usually the ceiling panels have certain steps, then the injection stage is entered before the sheets are connected. Polyurethane foam is injected into the bottom sheet, then polyurethane is injected into the sheet with the desired density and catalyst by automatic systems, after that it enters the main and important part, which is the press machine, which is very important and with temperature and Proper pressure is applied and finally it is cooled and packed.

- Discontinuous with polystyrene foam: this method is very similar to the polyurethane sample, where galvanized sheets are first given the desired shape in the forming machine and cut to the appropriate size, then the polystyrene foam is also cut by the cutting machine. It is cut to the right size and finally it is glued to the sheets with a special glue and pressed.

Continues:

This method is also called continuous or continuous. First, the raw materials for the production of panels, whether galvanized sheet, polyurethane foam or foam, enter the machine at the same time, and according to the customer’s needs and the sizes ordered by the robot Mechanical products are produced and cut and divided to the desired size and prepared for packaging.

In this method, devices are divided into two categories:

• Continuous polyurethane device:

1) Decoiler: In this part, the sheets enter the machine in the form of a coil and are opened by the decoiler, usually there are 4 decoilers in each line.

The upper coil and the lower coil are opened at the same time and lead to the roll machine by the conveyor belt.

2) Rolling device: this device consists of two internal and external parts, whose task is to create the desired design and form on the sheet, for example, in wall and ceiling sandwich panels, it is done by an external device, and forming and design on the part The interior of the sandwich panel is done by the inner part.

3) Injection device: before the top and bottom sheets reach each other, polyurethane foam is sprayed on the bottom sheet, then the injection device digitally and automatically injects the polyurethane foam raw materials placed in the tank using a strong catalyst. It is combined with the desired density and then injected by nozzle hoses.

4) Pressing part: The most basic part in sandwich panel production is the pressing machine, which plays a very important role. The length of this machine is between 12 and 15 meters. It is placed and pressed with the right pressure and temperature. This part is very important because the quality of the press guarantees the quality of the sandwiches.

5) Cooling device: due to the expansion of polyurethane foam and the chemical reactions that occur, a high temperature is produced, and if the panel is not cooled, it will come out of its shape and may lose its original state. The cooling part of these panels is placed for 5 to 7 minutes to reduce their temperature.

6) Sheeting part: After the panels have cooled down (sandwich panels by a fully automatic machine), they are collected and placed on top of each other and packed and loaded by the sheeting machine.

• Continuous polystyrene device:

This device works like polyurethane, but with the difference that polystyrene foam is used.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square