Investigation of soundproof sandwich panels in Iran

One of the problems of today’s life is noise pollution, which definitely has a great impact on the daily life of the public. To solve this problem, with the help of prefabricated tools, measures have been devised by today’s manufacturers and engineers, which have helped to use materials that have the ability to repel sound to some extent.

Sandwich panels are a new generation of prefabricated materials today, which have attracted the attention of most structural engineers. These panels have many uses due to their features. If it is to be used for a specific purpose, that unique feature should be strengthened.

These panels are very good insulation for moisture and rain penetration and fire. One of the applications of this product is sound insulation in various building construction industries where noise pollution control is very important. These sandwich panels are soundproof or It is called acoustic.

What materials are soundproof sandwich panels made of?

In general, the sandwich panel is offered in two types, ceiling and wall. It should be acknowledged that the sound-proof or acoustic sandwich panel is reinforced in such a way that it can absorb sounds with a frequency higher than 125 dB, which is like the sound of a jet engine has.

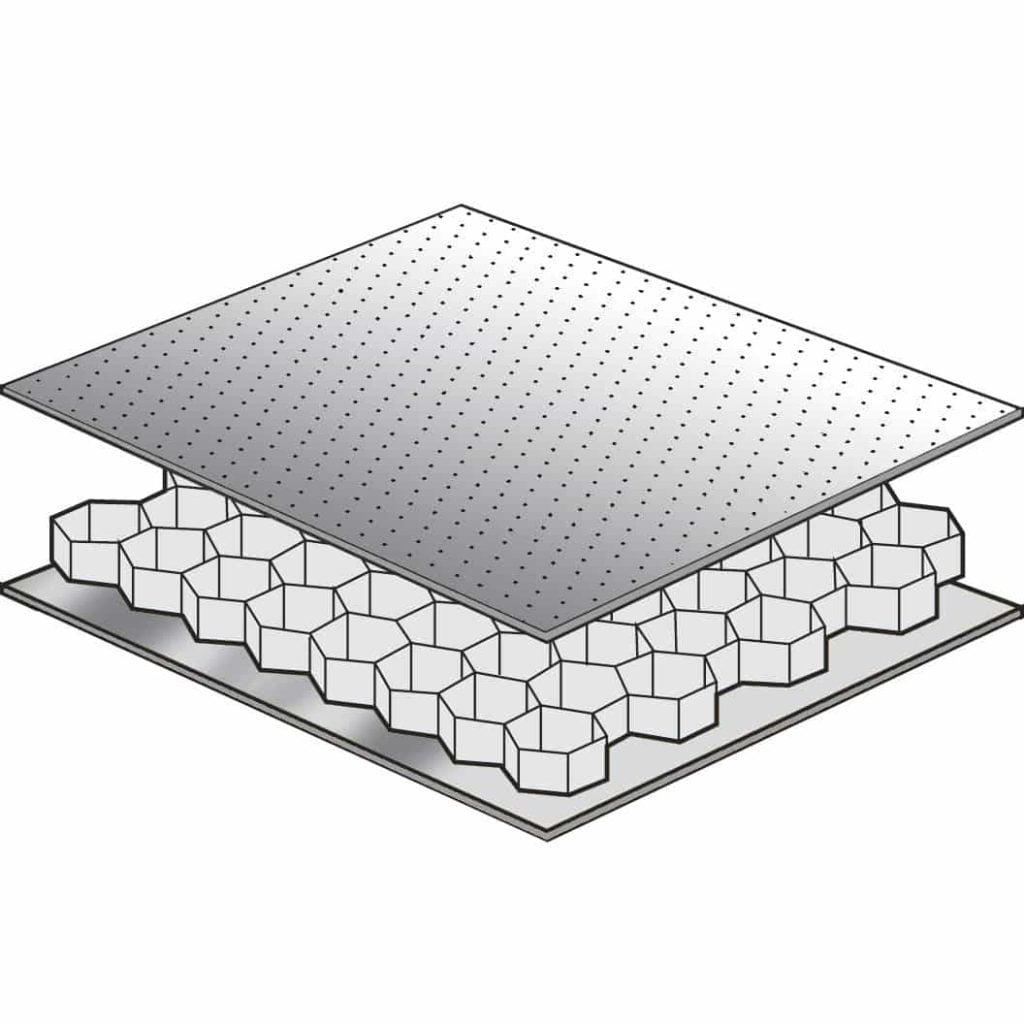

These panels, like other sandwich panels, are limited to galvanized sheets from the upper and lower layers, and the middle layer is insulating foam, which is often made of stone wool with a density of 80 or 120, and also two galvanized sheets. It is installed flat and the other is punched.

One of the many problems that we had until now, the sound production in trains, airplanes, and helicopters has been very high. This practical material helps to minimize noise pollution by using panel coverings on the inner wall of the helicopter cabin and In aircraft construction, this problem is minimized because the panel does not allow sound to pass through.

How does the soundproof sandwich panel neutralize the sound?

Galvanized sheets are easy to absorb and repel sound due to the high damping and high vibration of this material and due to its unique feature. These two characteristics are completely sufficient for sound rejection. Of course, one should consider that one of the galvanized sheets is flat and the other is perforated or punched, which greatly contributes to this natural mechanism.

The steps are such that first the sound enters from the first layer which is a punched galvanized sheet and hits the stone wool, where it is received and completely repels it. If the sound is small or has a long range, it passes through this layer and passes to the second layer, which is a simple galvanized sheet, and again hits the stone wool layer, and the sound is completely lost, and no sound enters inside. or it is not transferred out.

The types of sheets used in sandwich panels are as follows.

1) Alozinc sheet

2) Galvanized sheet

3) Aluminum sheet

1) One of the sheets used in making sandwich panels is aluzinc sheet, which is a combination of aluminum, zinc and silicon. This type of sheet has the necessary conditions in an environment with high acidity.

2) These panels are special for environments with high humidity. The material used in this Zn sheet is zinc with cathodic protection and it is produced in different sizes depending on the customer’s needs. This sheet is resistant to corrosion. And it is completely resistant to rust. One of the advantages of this sheet is its long life and high durability against natural factors. Low price and low cost are the characteristics of this type of sheet.

Steel and iron are controlled against corrosion, that’s why it is effectively used in making sandwich panels, cars and rabbets used in refrigerators and roofs.

3) Aluminum is one of the materials that is used in the industry after iron. The light weight and softness of this metal has made it flexible and it is completely resistant to corrosion and rust. It is practical.

Soundproof sandwich panel features

Before buying a soundproof sandwich panel, it is necessary to pay attention to its features

1) Ease of transportation

2) Fast installation and implementation

3) Stability against sunlight

4) Sound absorption and non-transmission to the surroundings

5) A suitable substitute for old materials such as brick and concrete

6) Sufficient durability against decay, corrosion, penetration and accumulation of microbes

7) Absence of absorption of heat, cold, and resistant to landslides

Applications of soundproof sandwich panels

These panels are very useful in noisy places due to their unique features. The use cases of these panels are:

1) metal production and welding workshops

2) sound recording laboratories

3) Music schools

4) Schools

5) Factories and industrial workshops

6) Cinema halls and amphitheatres

7) covering the walls

8) Train and airplane cabin

9) Aviation industry

Kimia Panel company produces all kinds of polyurethane sandwich panels with several years of brilliant experience in the field of producing all kinds of ceiling and wall sandwich panels, production and implementation and installation of all kinds of cold storage. That these contents have been brought to your attention.

You can use YouTube channel to watch videos.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square