Sandwich panel in Isfahan province

Isfahan sandwich panel is a prefabricated structure that has received a lot of attention from structural engineers and architects today. This new product is very similar to a sandwich, the outer layers of the sandwich panel are covered with galvanized sheet, aluzinc or aluminum. The middle part is injected with polyurethane, polystyrene, xps and rock wool materials. In this way, it creates three composite layers that create a completely connected and integrated structure.

Isfahan sandwich panel Kimia

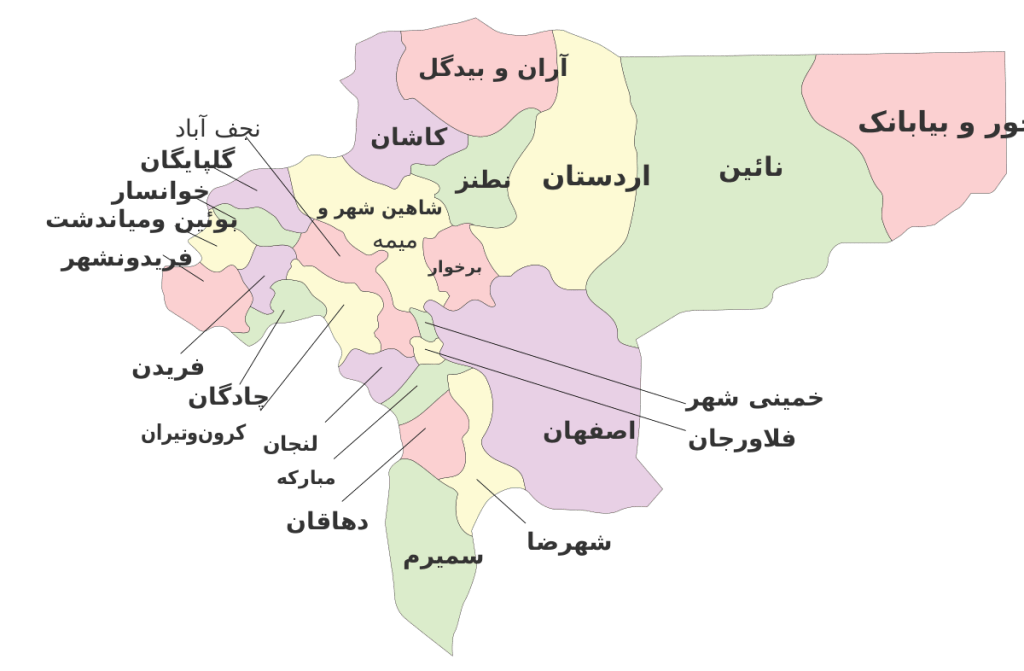

Isfahan province, centered in the city of Isfahan, is a historical metropolis with many years of history. This province is the third most populous city in Iran after Tehran and Mashhad and is known as the ninth most populous city in Western Asia. Also, this city is considered the 14th largest city in the Middle East. Isfahan city with an area of 551 square kilometers is the second largest city in Iran after Tehran. Due to its vast area, it has been chosen as the center of production of iron, building materials and petrochemicals.

The industrial city of Isfahan has many industries, including iron smelting, Mobarakeh steel complex, Isfahan polyacrylic company refinery and even numerous ceramic factories, tile making, and stone quarries, which have led to the strong economy of Isfahan.

Isfahan province also has other industries; which include corrugated sheet, ceramics, household appliances, cement factory, automobile industry, military industry, aircraft industry, manufacturing of gas equipment and facilities, textile. Kimia Panel, a producer of polyurethane sandwich panels, is a producer of ceiling and wall sandwich panels in Shiraz, Isfahan and neighboring cities of Fars province. This new product can be a good substitute for traditional and old materials and brick blades. It is very productive and useful because of its special features.

Types of Isfahan sandwich panels

What is the use of Isfahan sandwich panel?

Sandwich panel has a light and flexible structure. Therefore, it can be efficient in the construction of most structures; which include industrial factories, food and agricultural storage warehouses, construction of prefabricated shelters, sports facilities, poultry and mushroom breeding halls, airplane hangars, wheat silos, roof and shed walls, construction of fixed and mobile sheds, construction of all kinds of Clean room, container hotels, meat and dairy cold storage, dates, indoor swimming pools and relief units.

What are the advantages of Isfahan sandwich panel?

- Light and flexible structure and ease of transportation

- High safety against fire

- Resistant to solvents, lubricants, oils, acids, and fumes from industrial factories

- Resistant to damp and moisture caused by bad weather or rain

- Resistant to the growth of fungus, mold and insect infestation

- No corrosion by small rodents and vermin, anti-rot and rust

- Resistant to thermal energy, cold, sound

- Resistant to shear forces caused by earthquakes

- Ability to disinfect and wash

- Compatible with any type of climate

Types of Isfahan sandwich panels

Polyurethane sandwich panel

Polystyrene sandwich panel

Stone wool sandwich panel

Polyurethane sandwich panel: This product has a middle polyurethane core. The best type of sandwich panel insulation can be called. It has two types, PIR and PUR. PIR consists of a combination of polyol and isocyanurate, and PUR is a combination of polyol and isocyanate. In order to accelerate the performance of both methods, the presence of a catalyst is required. The density of the product is adjusted with B141 gas. These two main differences are the fireproof ability of the PIR panel. This has caused many to use this type of material.

Polystyrene sandwich panel: The middle core of this type of sandwich panel is covered with polystyrene foam or Unolite. Polystyrene panel is at a lower level for thermal and sound insulation. But compared to polyurethane, it is very light and has a cheap price.

Rock wool sandwich panel: The core of this product is covered with rock wool fibers. One of the important features of this product is its fire resistance, which is very impressive. Rock wool sandwich panels are used in recording studios that need good sound insulation. The fire resistance level of this product is higher than PIR type sandwich panels.

Roof sandwich panel: The thickness of this type of panel is between 4 and 25 cm, which is produced by injecting hard polyurethane foam with a density of 40+2. This panel has a low thermal conductivity. They are very resistant to the growth of plants and fungi. Because this product has a path for the flow of water caused by rain and snow; Steps have been installed that can guide the water path to Nadavan. Roof sandwich panels are used to cover the roof of industrial sheds, cold storage, warehouses, prefabricated buildings and airplane hangars.

Sandwich wall panel: a prefabricated material that has taken the place of traditional materials today, consists of three interconnected layers that are limited to the sheet on the sides and the middle core that is covered with polyurethane foam. This product is suitable for wall covering. The defined thickness for production is between 4 and 10 cm, which is produced according to the request and needs of the customer and the type of use.

Isfahan sandwich panel cover type

Double-sided sheet, single-sided sheet, single-foil, single-sided nylon sheet, single-sided sheet, single-sided paper, double-sided foil

Isfahan sandwich panel thickness

The thickness of the sandwich panel is between 4 and 25 cm, which can be produced according to the customer’s order and demand. Of course, the thickness of the panel is determined according to the type of use. The panels are composed of 5 interconnected layers, 2 layers of sheet and the middle core, which is placed between the two sides of a special adhesive and connects the layers. The foam considered in the central core of the panel is made of polyurethane foam, which has a density of about 40 kg/m3.

Isfahan sandwich panel color spectrum

Isfahan sandwich panel can be produced in various colors such as white, blue, red, silver, cream, gray, jade green, yellow, purple.

Isfahan sandwich panel installation

Prefabricated structures called sandwich panels are very important because of their unique features. They are very light, flexible and resistant. The presence of polyurethane materials in the central core of the panel makes them a good insulator for thermal energy, refrigeration, sound and moisture. It should be emphasized that this product is resistant to fire and has anti-fire properties.

This new product should be installed by efficient and professional people. If it is installed by beginners, it will result in many human and financial losses, and large amounts of sandwich panels may be wasted.

What points should be considered when installing a sandwich panel?

To connect the sandwich panel to the building skeleton, 1 to 2 mm thick flashing is used. They also benefit from flashing in the corners to connect the panels to each other. Polyurethane sprays are used to cover the seals. The installation of the panel is done with the help of screws with special washers so that it is more resistant to water caused by rain and snow and does not penetrate into the structure.

Cost reduction methods in Isfahan sandwich panel

This new structure has many features, the most important of which is cost optimization, which reduces the price and is affordable. This product significantly reduces costs compared to brick and cement blades. In order to lower the cost of using sandwich panels, there are several methods that include:

- It is possible to produce a sandwich panel as a single sheet, only a single sheet of metal is used.

- Reducing the thickness of the sheet from 0.5 to 0.4, which reduces the cost.

- Reducing the panel density from 40 kg to 30 kg, which definitely affects the price.

- Reducing the steps of the roof sandwich panel can change the price.

To know the price, you can contact the experienced experts and consultants of Kimia Panel.

Isfahan sandwich panel price

Due to market fluctuations, the price of sheet and polyurethane materials is changing daily, the price of Isfahan sandwich panel is determined as one square meter. The price of the sandwich panel depends on other factors, which are determined by the expert engineer based on the type of use, climatic conditions, and the amount of the budget. It includes the following.

- Wall or ceiling profile type

- The material of the sheet can be galvanized, aluzinc or aluminum. Preferably, in order to reduce the cost, you can choose the panels as a single sheet of Ecrofoil (this product is completely waterproof).

- As the thickness of the sheet increases, the weight of the panel and the price of the sandwich panel will increase. Therefore, in order to reduce the cost, the thickness of the bottom sheet can be considered less than that of the face.

- The color of the sheet in the inner space of the panel can be covered with white, and the outer space of the panel can be chosen in yellow, blue, orange, red.

- Polystyrene and polyurethane intermediate insulation are both useful due to their characteristics, but polyurethane has a better insulation and fire rate, but polystyrene is much cheaper.

- The thickness of the panel can be defined between 4 and 25 cm, but it should be noted that the greater the thickness, the greater the insulation property against thermal and cooling energy.

- The density of the central core depends on the needs and orders of the customer and the type of use, which can affect the price of the panel.

- The maximum width of the sandwich panel is about 980 mm, which can be changed, and it is also possible to make a panel with a smaller width. The size of the sandwich panel will be larger than the structure due to overlapping.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square