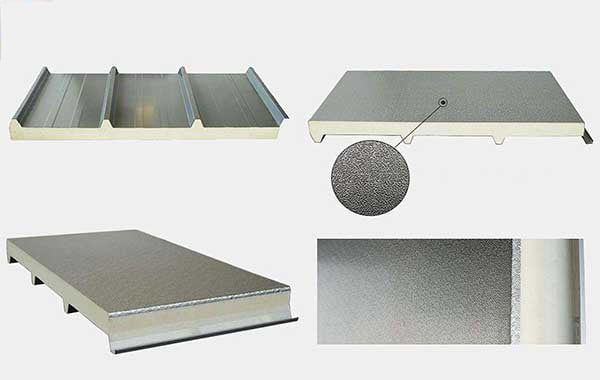

Review of one-sided foil sandwich panel and double-sided foil or nylon sandwich panel in iran

Sandwich panel, single sheet, single foil

The sandwich panel consists of three layers, and as mentioned before, one side is a colored sheet or metal coating such as galvanized, aluminum, or aluzinc, and the other layer is aluminum foil, and finally polyurethane foam is injected into the middle core. This foam has a very low thermal coefficient, acoustic property (sound absorption), resistant and light weight, which is one of its distinctive features.

This sandwich panel, one-sided, has a sheet cover and the other side is aluminum foil. The external part of this structure is in contact with more impact and pressure and may be exposed to natural factors such as rain, hail, or extreme temperature changes or radiation. should be exposed to direct sunlight, therefore the outer layer should be made of aluminum, galvanized, or aluzinc.

Its inner layer is aluminum foil, this sandwich panel is used in places that need a false ceiling or a false ceiling, and it is used in warehouse halls.

Types of aluminum foil

Threaded reinforced aluminum foil has mixed polyester fibers and has a very good performance against sunlight, heat and cold. Its range is between -30 degrees Celsius and +120 degrees Celsius.

Embossed aluminum foil is another type that is composed of 60 and 70% pure aluminum, which is created on the surface of the aluminum sheet by very heavy rollers after the production of the sheet.

It has caused it to have different applications. The sheets used in the sandwich panel are 0.5 and 0.7 mm thick and are available in various colors.

Double sided foil or nylon sandwich panel

The structure of the two-sided foil or nylon sandwich is such that both sides of the middle polyurethane core are without any sheet and are surrounded only by nylon or foil cover, and it is very light weight compared to other panels, and it is usually used on the floor of buildings or Their walls are used and the loss of heat and cold is minimized in the used cases. They usually work on it with concrete to avoid wasting energy.

Feature of double-sided foil or nylon sandwich panel

- These panels have a low conductivity coefficient against heat and cold due to their insulation.

- These panels show good resistance against mechanical and electrical forces, which makes them more useful.

- This foam is a suitable insulator for sound, the sound is transmitted between these open cells in the form of waves, and then it is absorbed by these cells and disappears.

It is hoped that these contents will be welcomed by you dear ones, you can visit the YouTube channel to watch the videos.

The advantages of using a sandwich panel, a single sheet, a single foil

- Because in this sandwich panel model, only one side of the sheet is used, it has a very light weight compared to other sandwich panels, which makes it easy to transport and install, and includes less cost.

- The outer cover of these panels is aluzinc or galvanized sheet and the inner cover is aluminum foil, which makes it resistant to decay, corrosion and rust.

Another characteristic of these panels is that they are resistant to fire and prevent fire from spreading.

- These panels are washable and prevent the entry of animals, vermin and rodents and are also antibacterial.

In addition to their light weight, these panels show great resistance against all kinds of impact and pressure.

- Due to the structure used in this panel, it has a small thickness and is more useful due to the removal of one layer.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square