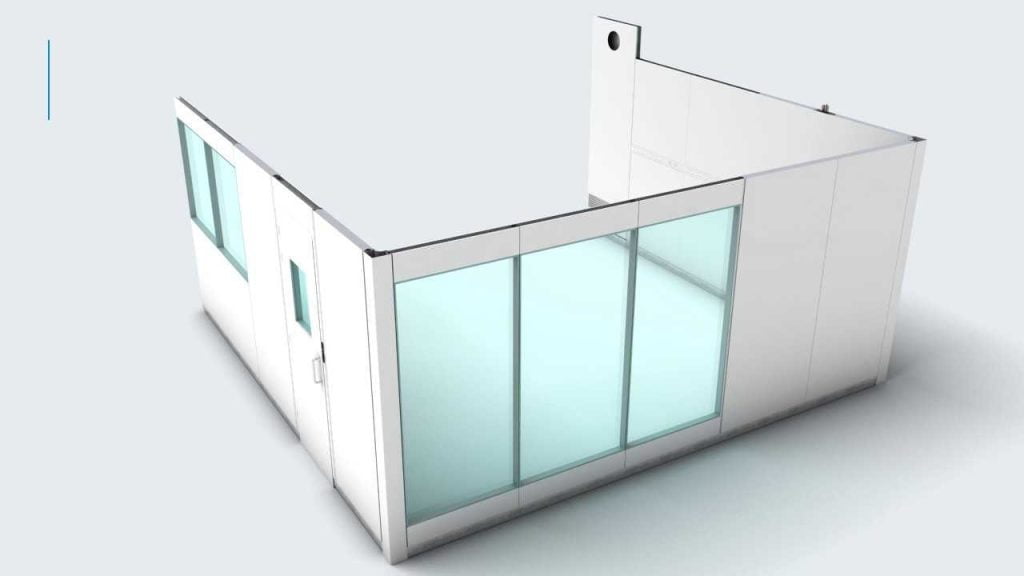

Clean room sandwich panel in Iran

Clean room sandwich panels are prefabricated and insulated materials, and as the name suggests, they have a structure like a sandwich, which consists of three separate layers glued together. Sandwich panel has a core called panel insulation. Some panel insulation foam includes XPS foam, polyurethane foam, glass wool foam or stone wool, polyethylene foam, polyurethane foam. These panels are also used in the construction of a clean room.

But what is a clean room? A clean room or clean room is a place where there should be no dust, germs, or vapors of liquids, or they should be as minimal as possible, and the entry and exit of air should be as little as possible. Even the people who enter there must wear special clothes and take an air shower. These rooms are used in food industry, aerospace industry, pharmaceutical, missile, nuclear industry, hospital equipment, which are used in these places due to the cleanliness and hygiene of these sandwich panels.

Advantages and characteristics of sandwich panels

One of the prominent features of sandwich panels is that due to their low weight, they are easy to transport and their installation is done quickly and easily. There is no need for building any more, and in the shortest time, a large structure will be created according to international standards and with high quality.

Also, sandwich panels have insulation against cold, heat, humidity and sound; For this reason, less energy is consumed and a lot of energy and related costs are saved. Therefore, because they are very well insulated, sandwich panels can be used in the refrigerator room of trucks and vans to cool the environment of the refrigerator because less energy is used.

They are also highly resistant to earthquakes, floods, storms, and unexpected events, and they have sufficient safety and strength, which has made them gain many fans.

Due to the low thickness of their walls, a lot of useful space is available inside the structure. Also, this advantage makes it possible to save on the costs of building foundations and the skeleton of high-rise buildings, and due to being cost-effective, they greatly reduce additional costs in projects.

Also, the use of non-flammable foam in sandwich panels has made these panels resistant to fire. At high temperature, they only accumulate and do not ignite; Therefore, it can be used in adjacent areas or public buildings, which is another important feature. All these features increase their resistance and thus increase their lifespan.

These sandwich panels are also attractive and beautiful in terms of appearance due to its various colors. Also, due to the reduction of the main and auxiliary columns and beams, their beauty has doubled and they are not subject to entanglement and blockage of columns or beams.

Sandwich panels are washable, which is one of the reasons why they are used in clean rooms. They also have a high resistance to decay, rust, corrosion and the growth of bacteria and microbes.

Disadvantages of poor quality sandwich panels

A high-quality sandwich panel must have all the features we mentioned above, such as high quality, optimization of fuel consumption, high resistance to moisture and chemicals, temperature, etc., as well as sufficient safety and strength against earthquakes and unexpected factors. It also has fire protection.

Whereas, if these sandwich panels are not of good quality, they cannot resist rust or moisture that causes mold and fungus to grow, and as a result, the structure collapses. Also, if its thickness is lower than the standard, its strength will decrease and it will not be resistant to accidents.

It cannot prevent fire and the heat passes through the joints of the sandwich panels. Therefore, you may face lower costs in the beginning; But in the end, you will have to pay several times the costs, and you will suffer financial and even personal losses. So it is better to always use high quality products.

Clean room sandwich panel equipment and components

The equipment should be able to absorb pollutants and suspended particles in the air and be resistant to disinfectants and detergents and can be washed and cleaned easily.

Window

There are two models of clean room windows. One type is a single-paned glass window and the other type is a double-paned window. Single-paned glass windows that are single-layered have a lower price, but they have high transparency, and their installation is also simple and convenient. Double-glazed windows have insulation, but they also have high transparency. These double-glazed windows also have a very beautiful appearance and are thermally insulated. A desiccant is placed in the window frame so that water vapor does not appear in the double-glazed window. Its main materials are glass, polysulfide rubber and desiccant, angled branches, hot edge separator and butyl rubber.

Clean room sliding door

These doors are especially suitable in places where there is less space, and because they are completely smooth and silent, they are a good option for rooms. One of the features of these doors is that they are sound-insulated and opening and closing is smooth and comfortable. These doors prevent dust, bacteria and air leakage very well. They are also fireproof, very durable, elegant, beautiful and reliable.

Clean room pass box

The box passing through other equipment are cleanrooms. In the clean room, there is a place called a postbox, which is used to transfer small items between clean areas and other clean areas or clean areas and non-clean areas, so that the doors of the clean room are opened and closed much less often to protect them from contamination.

They are made of stainless steel and are completely smooth. These doors are locked from both sides with electronic and mechanical connecting devices and are equipped with ultraviolet germicidal lamps. The pass box is usually used in micro technology and pharmaceutical factories, hospitals, food processing industries, biological laboratories, electronic factories and places that need air purification. These doors have a high efficiency filter to ensure the level of purification and also have a high sealing performance.

Emergency escape doors of clean rooms

These doors, fitted for emergency situations such as fire, allow for quicker evacuation in an emergency, with a crash bar on top with exit signs leading to it and installed on the exterior of the building. These doors have high strength and do not deform, they are completely smooth so that they can be cleaned easily. Also, they are comfortable, safe, air-tight and sound-insulated, and have constant color and brightness.

Clean room corner system

This system, which is used in the joints of the ceiling and floor of the partition, makes the circulation of the air flow smoother and prevents dust, bacteria, microorganisms, etc. from being created or accumulated in the corners. It also reduces collisions and saves space and gives a beautiful appearance and its surface is completely smooth and easy to clean.

Clean room ceiling system

This part is one of the important parts of the clean room system, which consists of a ceiling system and an aluminum alloy grid system. In addition to clean rooms, it has many applications in electronics, military, chemical industries, etc. There are also in lighting systems, broadcasting systems and fire fighting systems. These systems have very light weight and high strength and are easily installed. They are also so strong that you can even walk on its roof and can bear up to 140 kg.

Clean room floor

It consists of one or more different colors and has a delicate decorative texture, it is resistant to wear and chemical corrosion. Its other advantages are anti-pressure, anti-slip, waterproof, fire-proof, etc. Also, it has high resistance against acidic and alkaline materials and wear and prevents the production of bacteria and remains clean. Anyone can order its color according to their taste.

Clean room air conditioning equipment

This equipment provides the volume of air rotation per minute. With this, they perform the primary cleaning of pollutants and particles.

Air ducts

These electrical channels are designed from polyurethane or galvanized coating. They are designed to have the least amount of resistance to air flow and all their air outlets are closed.

Clean room doors

These doors have double-glazed glass, their surface is completely smooth, and they are special for the clean room, which is smooth and without protrusions.

Sound Modulators

These moderators make noise pollution to the minimum possible. They have low resistance to air flow and prevent unpleasant odors. They are also fireproof.

Thermal and sound insulation

All channels of the clean room are properly insulated and layered to prevent steam, heat, and noise from escaping.

Clean room tables and benches, air shower, filter fan, clean room towels and room clothes and pressure difference gauge are also important equipment of clean room.

For completely isolated environments, screws are usually not used in the sandwich panel of the clean room, so that there are no small grooves and it does not cause problems such as the formation of germs and all kinds of fungi.

Factors affecting the price of clean room

Various factors affect the cost of a clean room, for example, the cost of a pharmaceutical clean room is higher compared to other clean rooms. The higher the degree of air cleanliness, the higher its cost. Also, the more air change, the more air flow is needed. Air temperature and humidity, different pressures, automatic control and display, different levels of materials and other such things, all of which affect its cost and pricing.

In general, cleanroom design is classified into three stages. In the initial design, conceptual design and detail design, in order to determine the price, it is necessary to specify exactly what we want in each part. to be priced accordingly.

Aluminum sandwich panel

This structure is also used to build a clean room, but it is mostly used for industries such as building construction, automobile manufacturing, shipbuilding, etc. As you know, aluminum is a metal that is the best conductor of heat and electricity, and also has a high resistance to corrosion and is very light. For this reason, it is often used in construction, refrigeration, home appliances, license plate making and other industries.

This metal is also used in all types of structures in the aviation and marine industries, power transmission lines, vehicles, etc. due to its excellent ductility, corrosion resistance, good welding ability and high strength. Aluminum sandwich panels also have a great variety of colors, we can almost say that it has 40 different colors, which makes this structure have a very modern and stylish design. Also, due to the non-toxic nature of this material, it can be used in the health, pharmaceutical and food packaging industries.

Color sandwich panel

Sandwich panels are available in different colors and sizes. Among their most popular colors are glacier white, orange, orange, red, burnt brown, clay, pink, purple, silver, gray, jade green and cream. These colors give them a beautiful and attractive look. It also causes more longevity, durability of the coating, protection from wear and decay and dents of the structure. Of course, this coloring does not affect the price of the panels. All of them are painted in a kiln. These colors give a special beauty to the facade of the structure and attract more customers.

One of the important points that must be observed in sandwich panels is that all installation steps must be performed by experienced and expert personnel and all technical and safety points must be properly observed. Another thing is that we should not neglect the post-installation services and pay attention to it as well; Because negligence in any of these cases will cause us to face many consequences and cause a disaster and heavy costs for us.

To view the videos, you can refer to Aparat.

Dear customer, you can contact our consultants for more information about Kimia Panel Shiraz products.

Get in touch with us:

contact numbers:

Factory Address: Shiraz – Industrial Town – Som Square – Northern Sooreh Blvd. – Sa’i St.

End of 801 Street – 802 Street

Address of the sales office: Shiraz – first square